Elevator Lift Over Speed Governor Galvanized Steel Wire Rope Steel Hemp Core 8 12 13 16 10mm High-Rise High Low Speed

-

Highlight

High Low Speed Elevator Lift

,10mm Elevator Lift

-

Product NameElevator Lift Over Speed Governor Galvanized Steel Wire Rope Steel Hemp Core 8 12 13 16 10mm High-Rise High Low Speed

-

Model NumberElevator Lift Over Speed Governor Galvanized Steel Wire Rope Steel Hemp Core 8 12 13 16 10mm High-Rise High Low Speed

-

Delivery Time2-3 Working Days

-

Supply Ability10000pcs Per Month

-

TypeElevator Parts

-

Suitable ForEscalator

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

BrandSulab

-

DescriptionElevator Parts

-

ModelFB-9B

-

Place of OriginChina

-

Brand NameSULAB

-

Model NumberSteel Rope

-

Minimum Order Quantity1

-

Packaging DetailsCarton

-

Delivery Time2-3 working days

-

Payment TermsCompany Bank, Western union, alibaba, Paypal etc

-

Supply Ability10000pcs per month

Elevator Lift Over Speed Governor Galvanized Steel Wire Rope Steel Hemp Core 8 12 13 16 10mm High-Rise High Low Speed

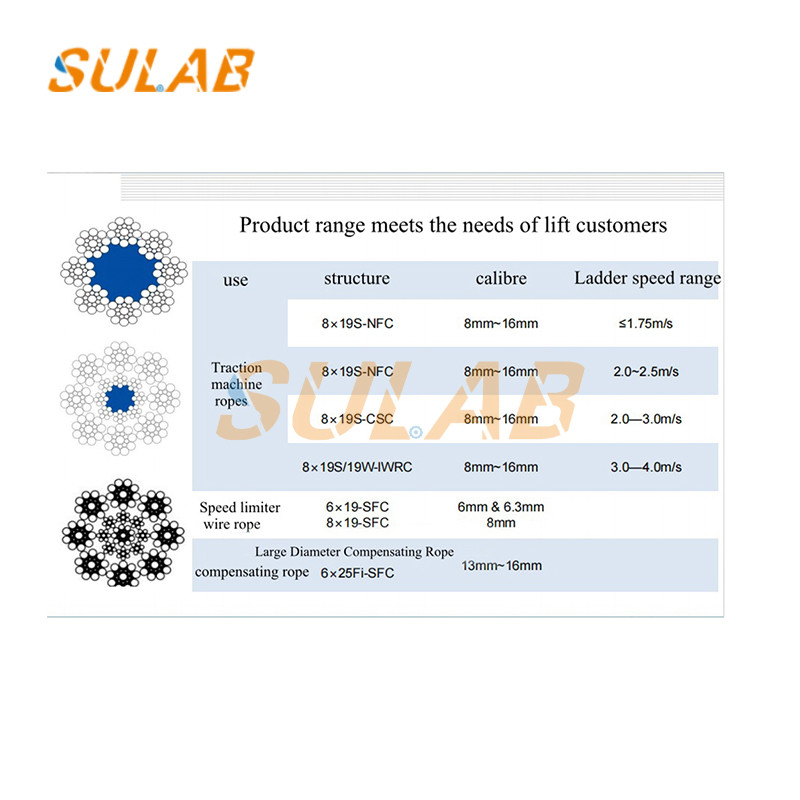

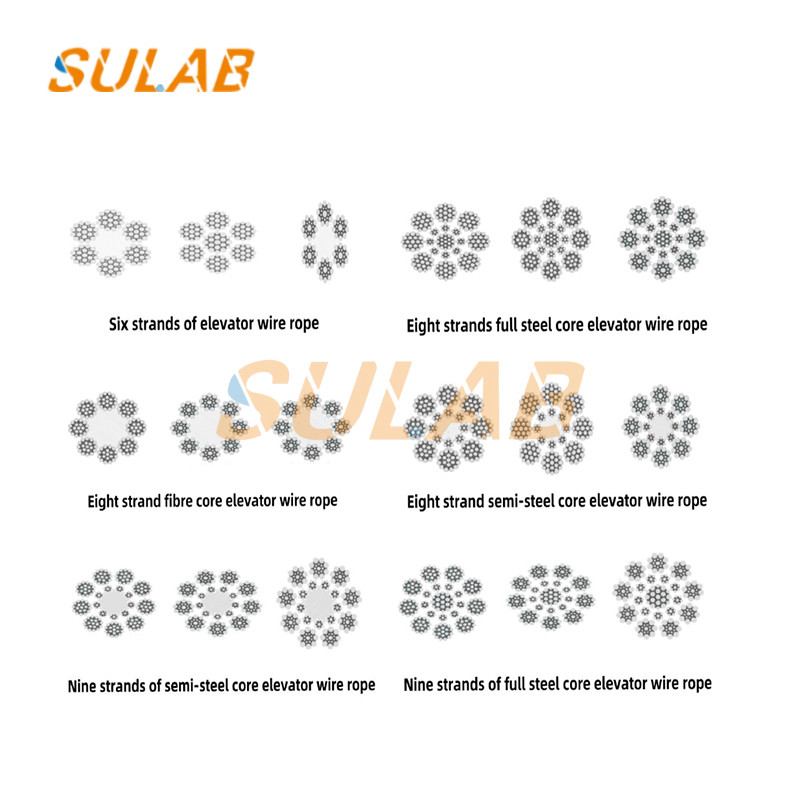

Details for Elevator Lift Over Speed Governor Speed limiter Galvanized Steel Wire Rope Steel Hemp Core 8 12 13 16 10mm High-Rise High Low Speed 8x19S-NFC 8x19S-CSC 8x19S/19WIWRC 6x19-SFC 8x19-SFC 6x25Fi-SFC

![]()

![]()

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pictures for Elevator Lift Over Speed Governor Speed limiter Galvanized Steel Wire Rope Steel Hemp Core 8 12 13 16 10mm High-Rise High Low Speed 8x19S-NFC 8x19S-CSC 8x19S/19WIWRC 6x19-SFC 8x19-SFC 6x25Fi-SFC

![]()

![]()

![]()

When the wire rope is working, the inside presents micro-motion friction in three-dimensional direction, which requires that the wire rope grease must have strong penetration performance, that is, the lubricant molecules and anti-wear agent components in the lubricant can penetrate into each wire. In addition, the wire rope grease must also have strong adhesion performance to ensure that it adheres evenly to each wire rope. There are usually several ways to lubricate and maintain the wire rope. One is to disassemble the wire rope and soak it in lubricating oil at a temperature of 80~100 degrees for about 2~4 hours. The other is to use a brush to brush the lubricant directly on the wire rope. The key is to master the brushing method and interval. Generally speaking, for a wire rope with a diameter of about 12mm, about 1 kg of lubricating grease is applied every 40 meters, and the brushing interval is about two weeks; another is to use a dedicated wire rope lubrication equipment to lubricate the wire rope. This method is the most convenient, but the equipment cost is high. The specific lubricant and lubrication method should be carried out according to the requirements of the wire rope manufacturer. At present, not many elevator maintenance units really pay attention to the lubrication and maintenance of wire ropes. Many units are used to replacing new wire ropes without paying attention to lubrication management. This is only one aspect of ensuring the safe use of wire ropes. In addition, it is also necessary to check the peripheral conditions of wire rope use, such as the surface wear of the traction sheave groove and the geometric dimensions of the sheave groove, to ensure that the wire rope is always in good contact during operation to reduce friction and ensure safe operation of the elevator.