Original Yaskawa Inverter PG Card PG-B3 PG-X3 PG-E3 L1000A H1000 A1000

-

Highlight

L1000A Yaskawa Inverter PG Card

,H1000 Yaskawa Inverter PG Card

,Original Yaskawa Inverter PG Card

-

BrandYaskawa

-

DescriptionElevator PG Card

-

ModelPG-E3

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

BrandSulab

-

DescriptionElevator Parts

-

ModelFB-9B

-

Brand NameYaskawa

-

Model NumberPG-E3

-

Minimum Order Quantity1

-

Delivery Time2-3 working days

-

Payment TermsT/T,Western Union,MoneyGram

Original Yaskawa Inverter PG Card PG-B3 PG-X3 PG-E3 L1000A H1000 A1000

Original Yaskawa Inverter PG Card PG-B3 PG-X3 PG-E3 L1000A H1000 A1000

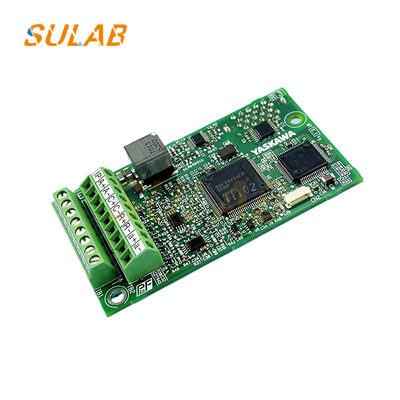

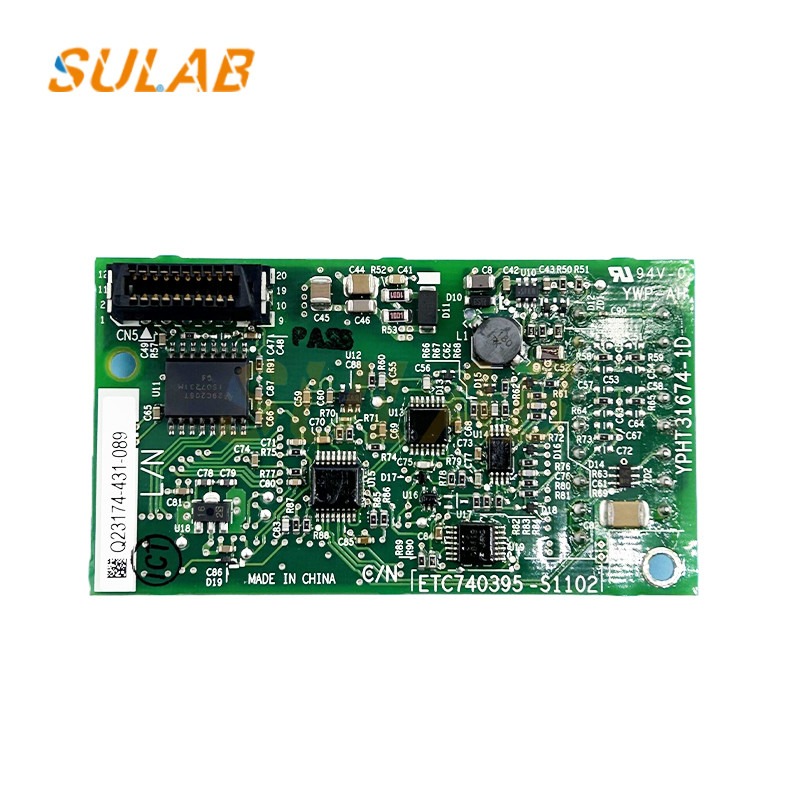

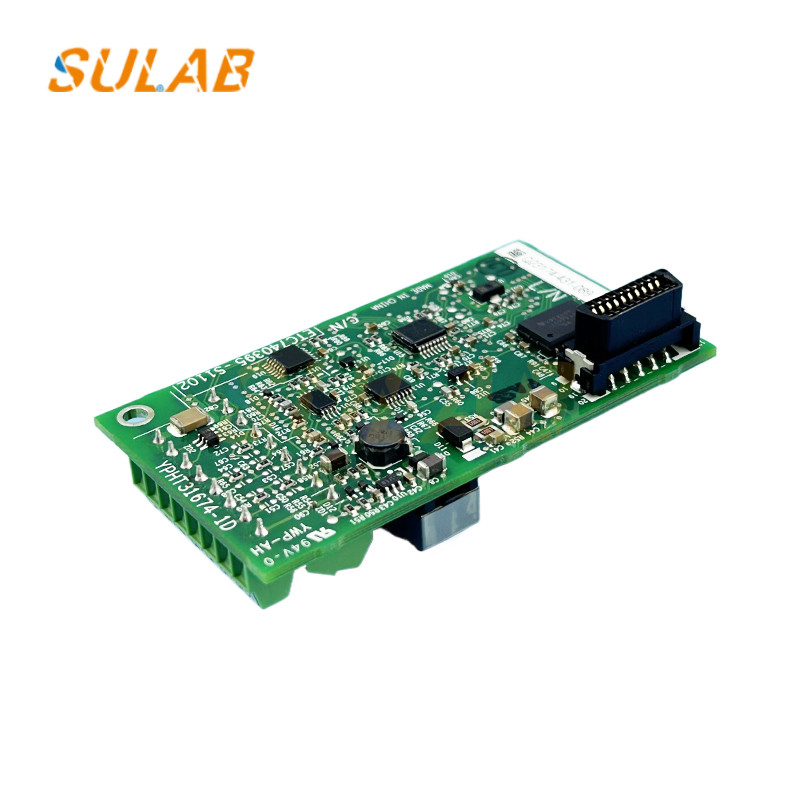

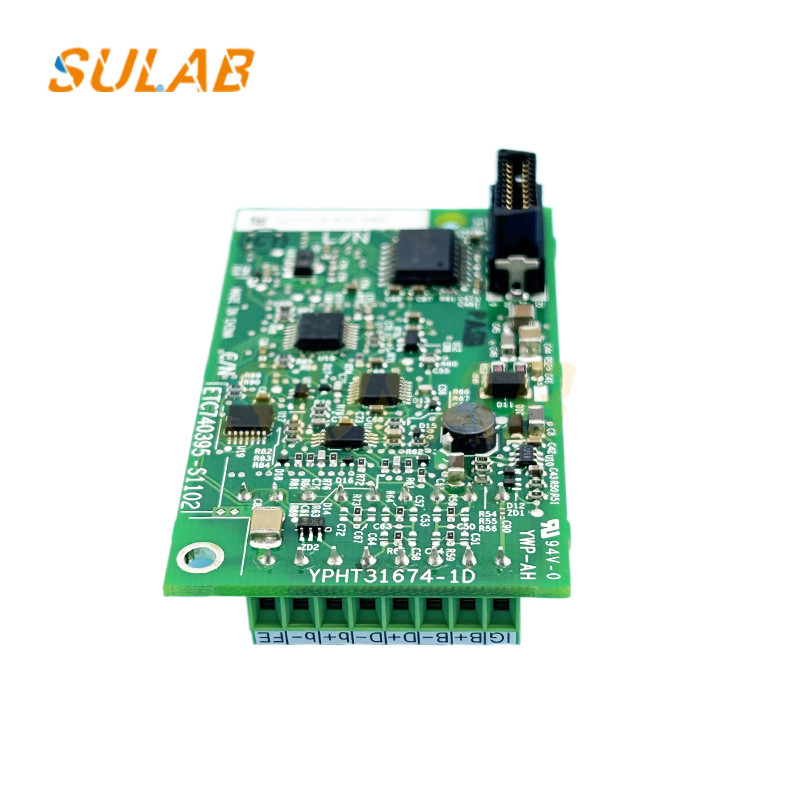

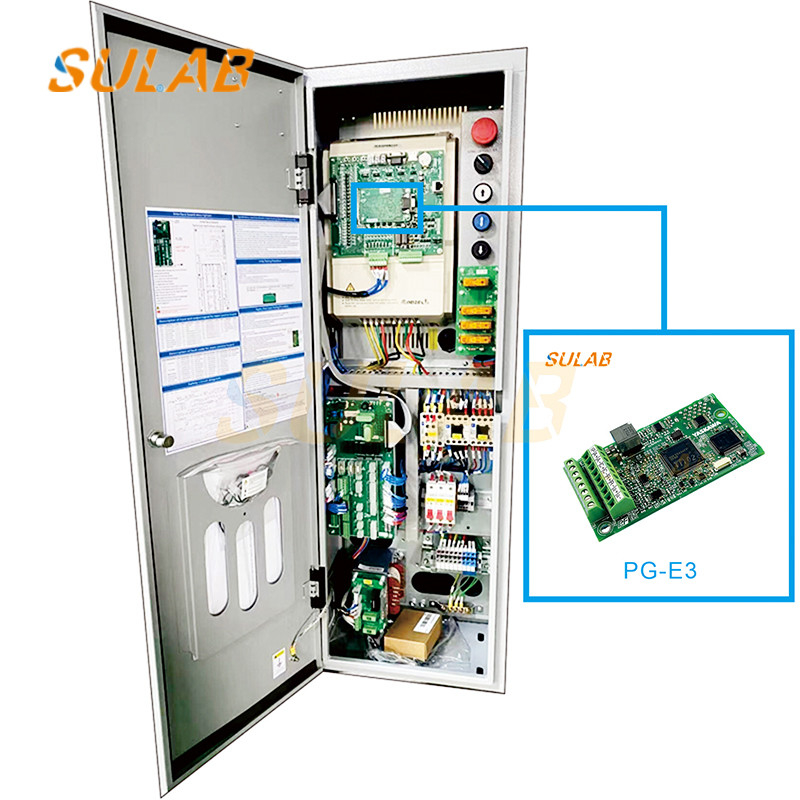

Yaskawa PG - E3 is a speed card for inverters, also known as an encoder feedback card, launched by Yaskawa Electric. The following is a detailed introduction:

| Brand | Yaskawa |

| Description | Elevator PG card |

| Model | PG-E3 |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |