-

Highlight

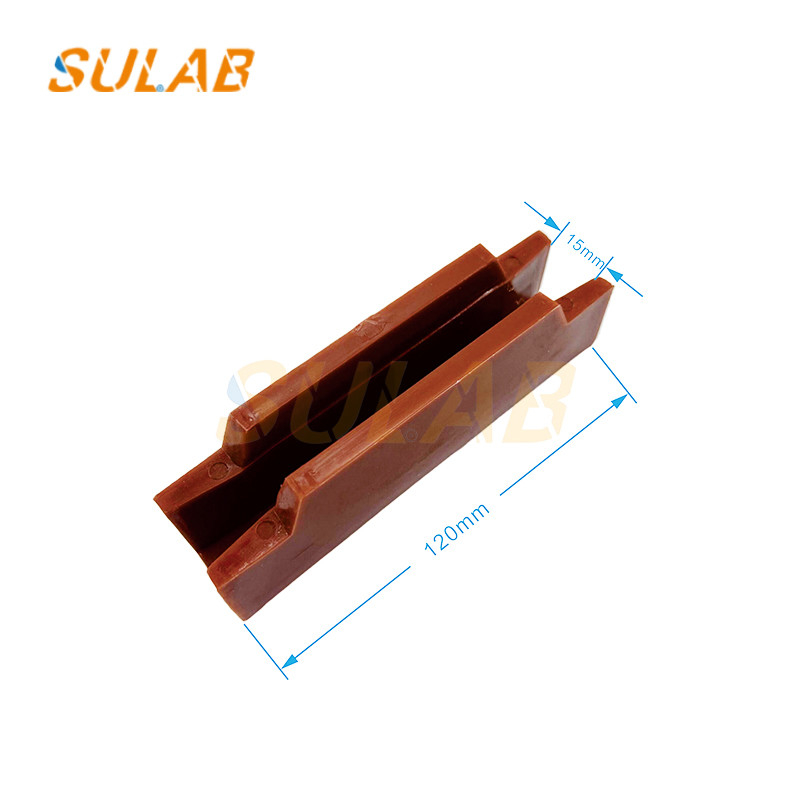

Elevator counterweight guide shoe

,Elevator Spare Parts guide shoe

,Elevator counterweight guide shoe lining

-

Elevator PartsDoor Operator Frequency Converter

-

OriginalChina

-

Quality100%NEW

-

Warranty Time12 Months

-

UsageElevator

-

PackageStandard Export Package

-

DeliveryDelivery: DHL,TNT,FedEx,Air,Sea

-

BrandSulab

-

DescriptionElevator Parts

-

ModelFB-9B

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model NumberSULAB

-

Minimum Order Quantity2

-

Delivery Time5-8working days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

Elevator Counterweight Guide Shoe Shoe Lining Elevator Spare Parts

Key Features:

✔ High Wear Resistance – Made from durable materials (such as composite polymers or nylon) to withstand continuous friction against guide rails.

✔ Low Friction Coefficient – Ensures smooth movement of the counterweight, reducing energy consumption.

✔ Shock Absorption – Helps dampen vibrations and noise for a quieter elevator operation.

✔ Corrosion & Moisture Resistant – Suitable for various environmental conditions, including high humidity.

✔ Precision Fit – Designed to match standard guide shoe dimensions for easy installation.

✔ Long Service Life – Reduces maintenance frequency and replacement costs.

Applications:

-

Used in traction elevator counterweight systems to guide and stabilize movement.

-

Compatible with various elevator models (Otis, Schindler, KONE, ThyssenKrupp, Mitsubishi, etc.).

Materials Available:

-

Polymer-Based Linings (e.g., UHMW-PE, Nylon) – For standard applications.

-

Metal-Backed Linings – For heavy-duty use.

-

Lubricated or Self-Lubricating Options – For reduced maintenance needs.

Benefits:

✅ Smoother elevator operation with reduced jerking or sticking.

✅ Extended guide rail and shoe life by minimizing metal-on-metal contact.

✅ Lower maintenance costs due to reduced wear and tear.

✅ Improved passenger comfort with noise and vibration reduction.

Installation:

-

Easily replaceable with standard tools.

-

Available in multiple sizes and thicknesses to fit different guide shoe models.