Elevator Wire Rope Wheel Door Head Rope Wheel Heavy Hammer Wheel Wire Rope Pulley Transmission Hanging Wheel 60-11-6200 Ordinary

-

Highlight

Heavy Hammer Wheel wire rope pulley

,Elevator wire rope pulley

,Hanging Wheel wire rope pulley

-

ItemDetails

-

BrandSULAB

-

Model60-11-6200 Ordinary

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 3-5working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal, Personal Bank Etc

-

DescriptionElevator Parts

-

ModelFB-9B

-

ApplicableElevator

-

Delivery TimeNormally 2-3 Working Days After Payment

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand Namesulab

-

Model Number60-11-6200 Ordinary

-

Minimum Order Quantity1pcs

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

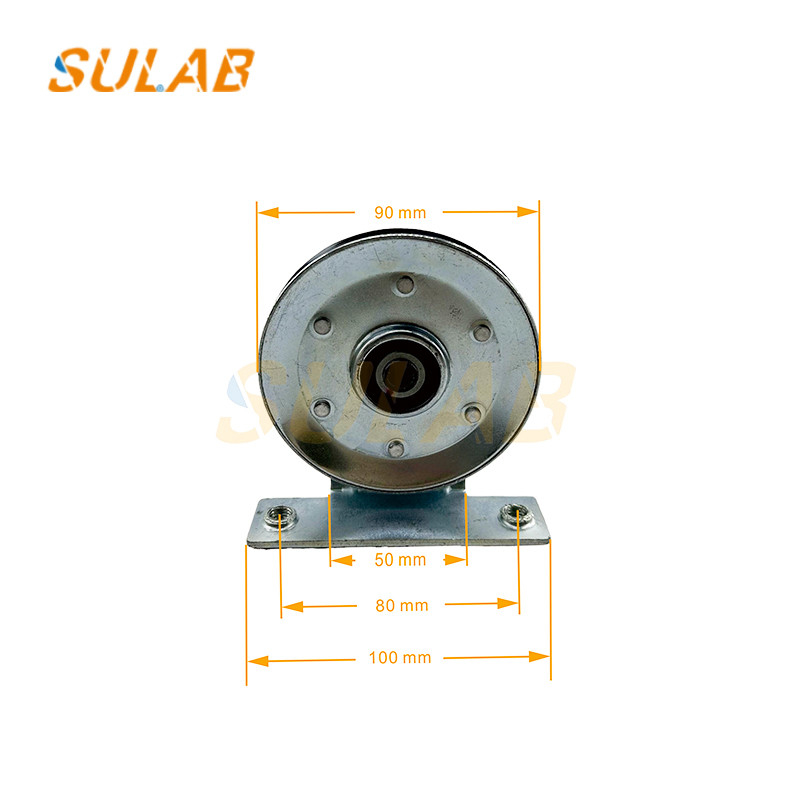

Elevator Wire Rope Wheel Door Head Rope Wheel Heavy Hammer Wheel Wire Rope Pulley Transmission Hanging Wheel 60-11-6200 Ordinary

Elevator wire rope wheel door head rope wheel heavy hammer wheel wire rope pulley transmission hanging wheel 60-11-6200 Ordinary

Preparation before installation

Determine the model and specifications: According to the load capacity, speed and other parameters of the elevator, select the appropriate model and specification of the wire rope pulley to ensure that it matches the design requirements of the elevator, including wheel diameter, groove type, material and other aspects.

Check the quality of components: Conduct a comprehensive inspection of the wire rope pulley to check for defects such as cracks, deformation, wear, etc., and ensure that the surface of the wheel groove is smooth, without burrs, protrusions, etc., so as not to affect the operation and service life of the wire rope.

Prepare tools and equipment: such as lifting tools (hand hoists, winches, etc.), mounting brackets, wrenches, pliers, levels, plumb lines, wire rope clamps, lubricants, etc.

Clean up the installation site: Remove debris, dust and oil stains in the installation area such as the shaft and machine room, keep the environment clean and tidy, and create good conditions for installation work.

Installation steps

| Item | Details |

| Brand | SULAB |

| Model | 60-11-6200 Ordinary |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 3-5working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal, Personal bank etc |

Debugging and inspection after installation

Check installation accuracy: Use measuring tools to check the installation position, horizontality, verticality and other parameters of the wire rope pulley again to ensure that they meet the installation requirements and relevant standards.

Adjust wire rope tension: Use tensioning devices or other methods to adjust the tension of the wire rope so that the tension of each wire rope is uniform. Generally, a tension tester can be used for measurement and adjustment to ensure that the wire rope is balanced during operation.

Trial run: After completing the installation and debugging, conduct a trial run of the elevator. Observe the operation of the wire rope pulley and wire rope, check for abnormal noise, vibration, friction, etc., and check whether the elevator's operating speed, leveling accuracy and other indicators meet the requirements.