-

Highlight

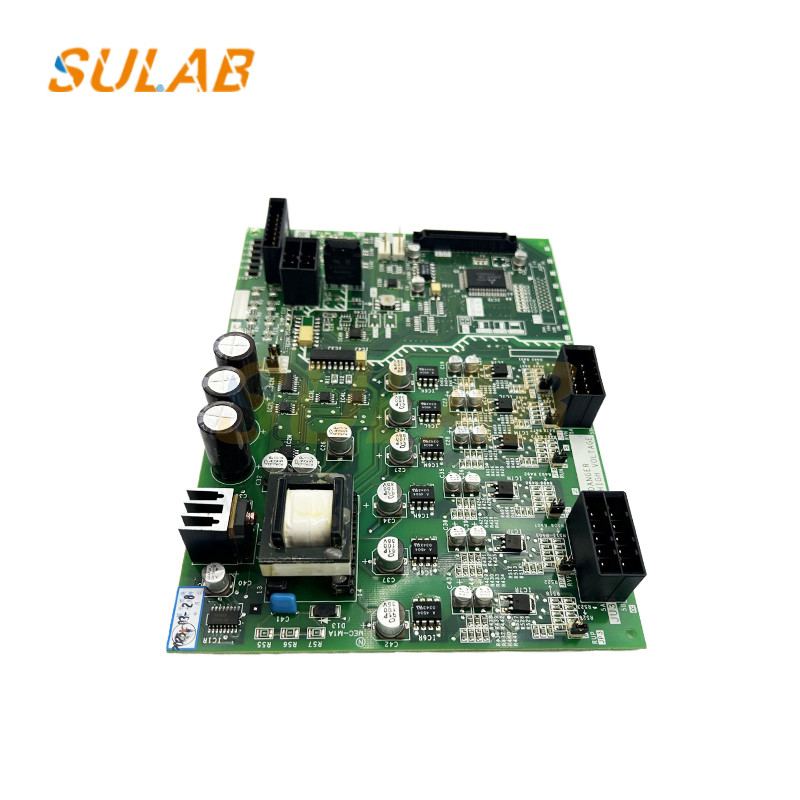

Mitsubishi PCB Board

,Mitsubishi KCR-759C PCB Board

,Elevator PCB Board

-

PackagesCarton, Wooden Case, Pallet Etc

-

Quality100%NEW

-

ConditionNew

-

Product TypeElevator Parts

-

TransportationClients' Requestment

-

BrandSulab

-

DescriptionElevator Parts

-

ModelFB-9B

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameMitsubishi

-

Model NumberKCR-759C

-

Minimum Order Quantity1

-

Delivery Time5-8working days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

Elevator PCB Board Mitsubishi KCR-759C Elevator Parts

1. General Specifications

-

Model: KCR-759C

-

Application: Elevator control system (likely for door control, signal processing, or motor management)

-

Compatibility: Designed for Mitsubishi elevator models (exact compatibility depends on the series)

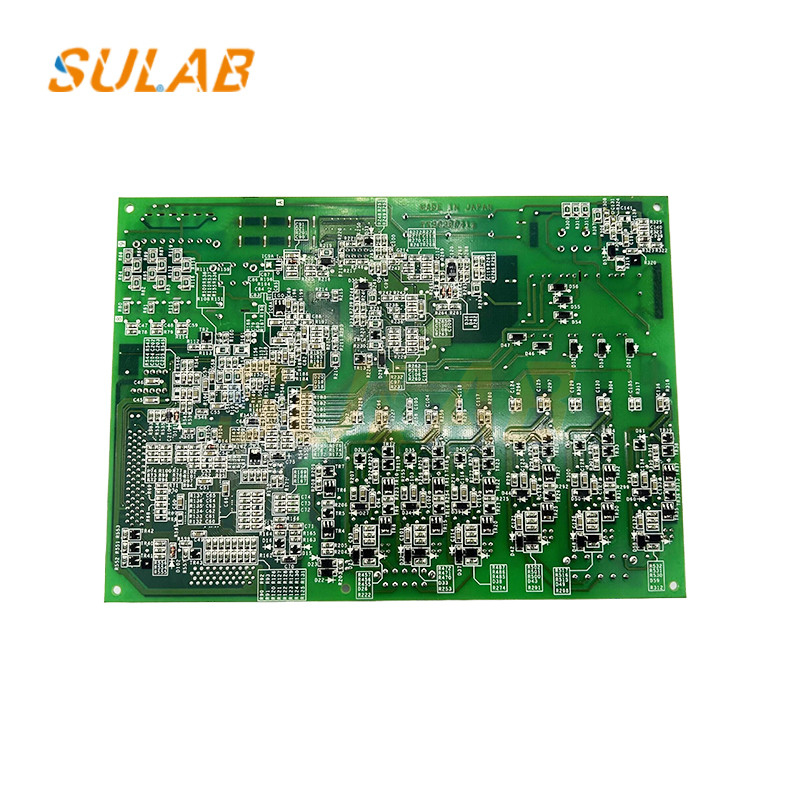

2. PCB Design & Manufacturing

-

Layer Count: Likely a 4-6 layer PCB (for signal integrity and power distribution)

-

Material: FR-4 (flame-retardant epoxy laminate)

-

Copper Thickness: 1oz or 2oz (for power handling)

-

Surface Finish: Lead-free HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold) for corrosion resistance

3. Key Components

-

Microcontroller/Processor: Mitsubishi-specific IC (possibly a proprietary Mitsubishi chip or a Renesas/Microchip-based controller)

-

Power Regulation: Voltage regulators (5V, 12V, 24V DC)

-

Relays/Solid-State Switches: For motor/door control

-

Optocouplers/Isolators: For signal isolation and noise reduction

-

Connectors: High-durability headers for wiring harnesses

-

Protection Circuits: Fuses, TVS diodes, and EMI filters

4. Production Process

-

Schematic & Layout Design – Designed using CAD tools (Altium, Eagle, or Mitsubishi’s proprietary software).

-

PCB Fabrication – Etching, drilling, and layer stacking.

-

Component Sourcing – OEM-approved components (Mitsubishi may use specialized suppliers).

-

SMT Assembly – Automated pick-and-place machines for SMD components.

-

Through-Hole Assembly – Manual or wave soldering for larger components.

-

Testing & QC –

-

In-Circuit Testing (ICT) – Verifies electrical connections.

-

Functional Testing – Simulates elevator operation.

-

Environmental Stress Testing – Checks for vibration/temperature resistance.

-

5. Compliance & Certifications

-

Safety Standards: EN 81-20 (elevator safety), UL/CE (if applicable)

-

EMC Compliance: EN 61000-6-2 (immunity), EN 61000-6-4 (emissions)

6. Common Failure Points & Repairs

-

Burned traces (due to power surges)

-

Failed relays (mechanical wear)

-

Corroded connectors (humidity exposure)

-

Faulty capacitors (electrolytic aging)

7. Replacement & Availability

-

OEM Part: Must be sourced from Mitsubishi or authorized distributors.

-

Aftermarket Alternatives: Rare due to proprietary design.

-

Refurbished Units: Sometimes available from elevator part suppliers.