-

Highlight

Escalator Handrail Guide Roller

,Spare Parts Handrail Guide Roller

,GAA456DH1 Handrail Guide Roller

-

Stock1000 Pcs Available

-

Delivery3-5 Working Days

-

TransportationAir, Sea, Express

-

ShippingDHL, Fedex, UPS, Air , Sea Etc

-

PackagesCarton, Wooden Case, Pallet Etc

-

Quality100%NEW

-

BrandSulab

-

DescriptionElevator Parts

-

ModelFB-9B

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSUBLAB

-

Model NumberGAA456DH1

-

Minimum Order Quantity1

-

Delivery Time5-8WORKING DAYS

-

Payment TermsD/A,L/C,D/P,T/T,Western Union,MoneyGram

Handrail Guide Roller GAA456DH1 Escalator Spare Parts

Product Name:

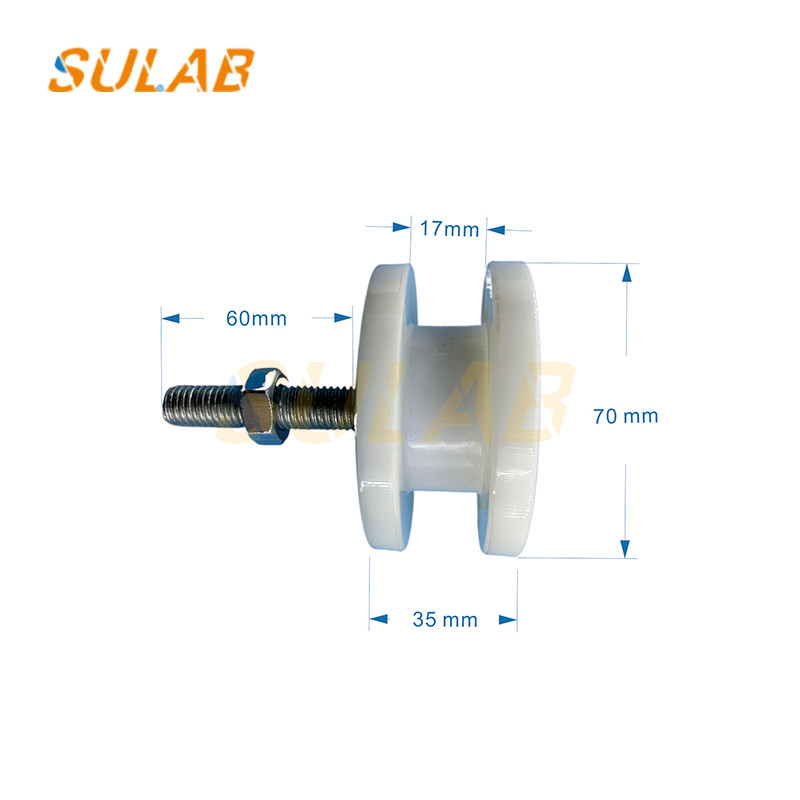

Handrail Guide Roller – Model GAA456DH1

Application:

Used in escalators, moving walkways, and other passenger conveyor systems to ensure smooth and stable handrail movement.

Key Features:

-

Material:

-

High-quality polymer or composite roller for durability and low friction.

-

Stainless steel or corrosion-resistant metal inner bearing housing.

-

-

Design:

-

Precision-engineered for smooth rotation and reduced wear.

-

Sealed bearing system to prevent dust and moisture ingress.

-

Noise-reducing construction for quiet operation.

-

-

Compatibility:

-

Designed to meet industry standards (e.g., EN 115, ASME A17.1).

-

Fits various escalator and moving walkway models (compatibility should be verified with OEM specifications).

-

Technical Specifications:

-

Roller Diameter: ~45-50mm (exact size may vary)

-

Bore Diameter: Standard (e.g., 10mm, 12mm – confirm based on model)

-

Load Capacity: Suitable for continuous operation under typical handrail tension.

-

Operating Temperature Range: -20°C to +60°C (depending on material)

Manufacturing Process:

-

Material Selection: High-grade polymers (e.g., nylon, POM) or rubber-coated rollers for grip and longevity.

-

Precision Machining: CNC machining for consistent dimensions.

-

Bearing Assembly: High-quality sealed bearings for smooth rotation.

-

Quality Testing:

-

Load and rotation tests.

-

Wear resistance and friction checks.

-

Environmental (temperature/humidity) testing.

-

Packaging:

-

Individually packed in anti-static or protective packaging.

-

Bulk packaging available for OEM orders.

Certifications & Compliance:

-

CE, ISO 9001, or other industry-specific certifications (if applicable).

-

Compliance with escalator safety standards.

Maintenance & Lifespan:

-

Requires minimal maintenance due to sealed bearings.

-

Typical lifespan: 5–10 years depending on usage conditions.