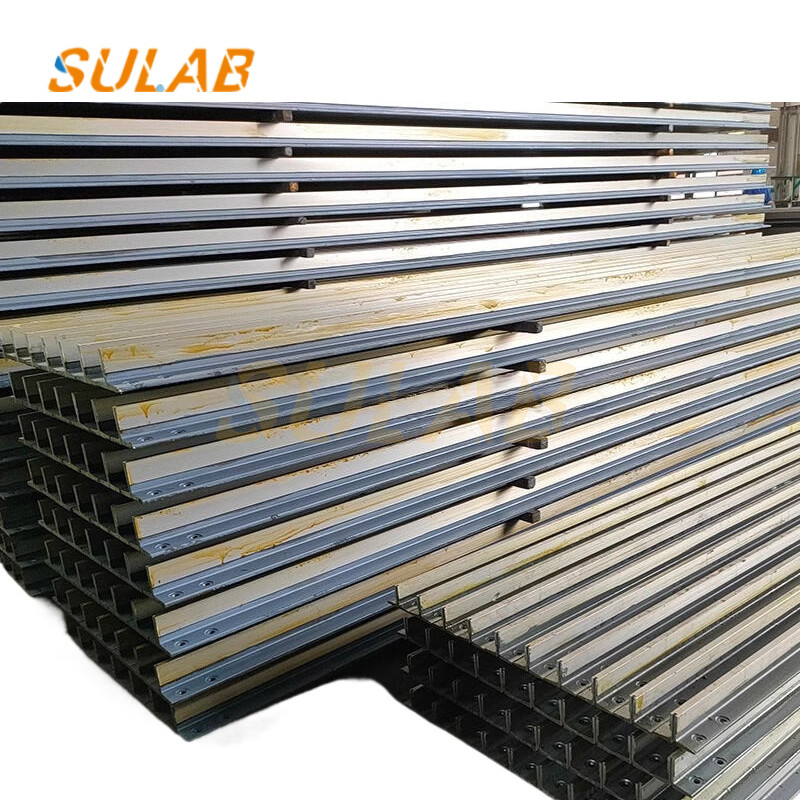

ELEVATOR ACCESSORIES RAIL SOLID RAIL T-RAIL T-STEEL LIFTING RAIL AUTOMATION RAIL SOLID RAIL T89

-

Highlight

elevator T-rail solid rail

,lift automation steel rail

,T89 elevator lifting rail

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelT89

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

DescriptionElevator Parts

-

ModelFB-9B

-

Brand Namesulab

-

Model NumberT89

-

Minimum Order Quantity1pcs

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

ELEVATOR ACCESSORIES RAIL SOLID RAIL T-RAIL T-STEEL LIFTING RAIL AUTOMATION RAIL SOLID RAIL T89

ELEVATOR ACCESSORIES RAIL SOLID RAIL T-RAIL T-STEEL LIFTING RAIL AUTOMATION RAIL SOLID RAIL T89

Installation and maintenance

Installation requirements: Each guide rail has at least two guide rail brackets, with a spacing of 2-2.5m, and the horizontality of the guide rail bracket is not more than 1.5%. The guide rail should be fixed on the guide rail bracket with a pressure plate. The distance deviation between the top surfaces of the two rows of guide rails is: + 2-0 for the car; + 3-0 for the counterweight guide rail.

Maintenance points: Regularly check the surface quality of the guide rail. If wear, deformation, corrosion, etc. are found, they should be repaired or replaced in time; check the connection parts of the guide rail to ensure that the connection is firm and there is no looseness; clean and lubricate the guide rail regularly to reduce the friction between the guide shoe and the guide rail.

| Brand | SULAB |

| Description | Elevator parts |

| Model | T89 |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

Guiding function

Provide precise vertical guiding paths for the elevator car and counterweight device, ensure that they run smoothly up and down along the predetermined track in the shaft, prevent the car and counterweight from lateral swing or deviation during operation, and ensure the linearity and stability of the elevator operation.

Load-bearing function

It can bear the weight of the elevator car, counterweight, and the people and goods they carry, and transfer these weights evenly to the basic structure of the elevator shaft. The strength and rigidity design of the T89 guide rail enables it to withstand various dynamic and static loads during the operation of the elevator, including the impact force generated by the acceleration, deceleration and emergency braking of the elevator.

Safety function

In conjunction with the elevator's safety clamp system, when the elevator encounters an emergency such as overspeed or loss of control, the safety clamp will act quickly to clamp the car or counterweight device tightly on the guide rail, causing the elevator to stop running immediately, thereby avoiding serious accidents such as falling or hitting the top of the elevator, and ensuring the safety of passengers and equipment.

Buffering function

During the operation of the elevator, the guide rail can absorb and buffer the vibration and impact force generated by the up and down movement of the elevator car and the counterweight device through its own elastic deformation and friction, reduce the noise and vibration during the operation of the elevator, and improve the riding comfort of passengers.

Positioning function

Provide installation reference for various sensors and limit devices of the elevator, help accurately determine the position of the elevator car in the shaft, realize the functions of floor positioning and leveling of the elevator, ensure that the elevator can accurately stop at each floor, and facilitate passengers to enter and exit.