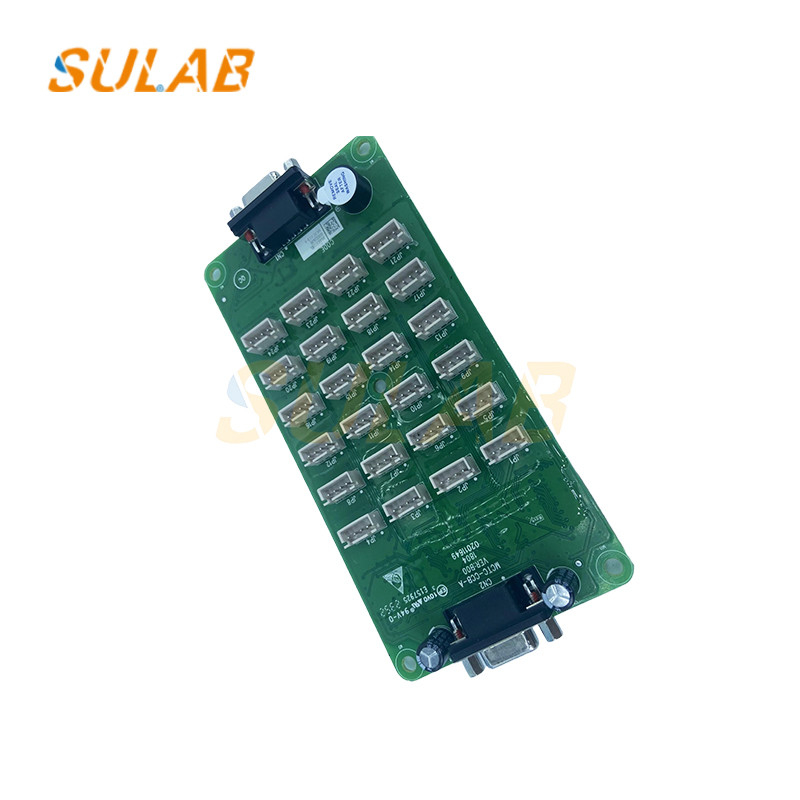

Monarch Elevator PCB Board MCTC-CCB-A Elevator Push Button PCB Elevator Sparts Parts

-

Highlight

Elevator Sparts Parts PCB Board

,Elevator Push Button PCB

,Monarch Elevator PCB Board

-

ApplicationElevator Maintenance

-

Transportation ModeEMS Or UPS) /LCL By Sea Or Train

-

TypeSpare Parts

-

PackagesCarton, Wooden Case, Pallet Etc

-

BrandSulab

-

DescriptionElevator Parts

-

ModelFB-9B

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameMonarch

-

Model NumberMCTC-CCB-A

-

Minimum Order Quantity1

-

Delivery Time5-8working days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

Monarch Elevator PCB Board MCTC-CCB-A Elevator Push Button PCB Elevator Sparts Parts

Production Description of MCTC-CCB-A PCB Board

-

Function & Application

-

Likely serves as a control or communication interface board in Monarch elevator systems.

-

May handle functions such as car control, signal processing, door operation, or elevator dispatch communication.

-

Could be part of a Modular Control System (MCTC series).

-

-

Key Features

-

Microcontroller/Processor-Based – Manages elevator logic and safety functions.

-

Input/Output Interfaces – Connects to buttons, sensors, and elevator drive systems.

-

Communication Protocols – May support CAN bus, RS-485, or proprietary Monarch protocols.

-

Safety Compliance – Likely meets EN 81-20/50, ASME A17.1, or other elevator safety standards.

-

Robust Design – Built for long-term reliability in harsh elevator environments.

-

-

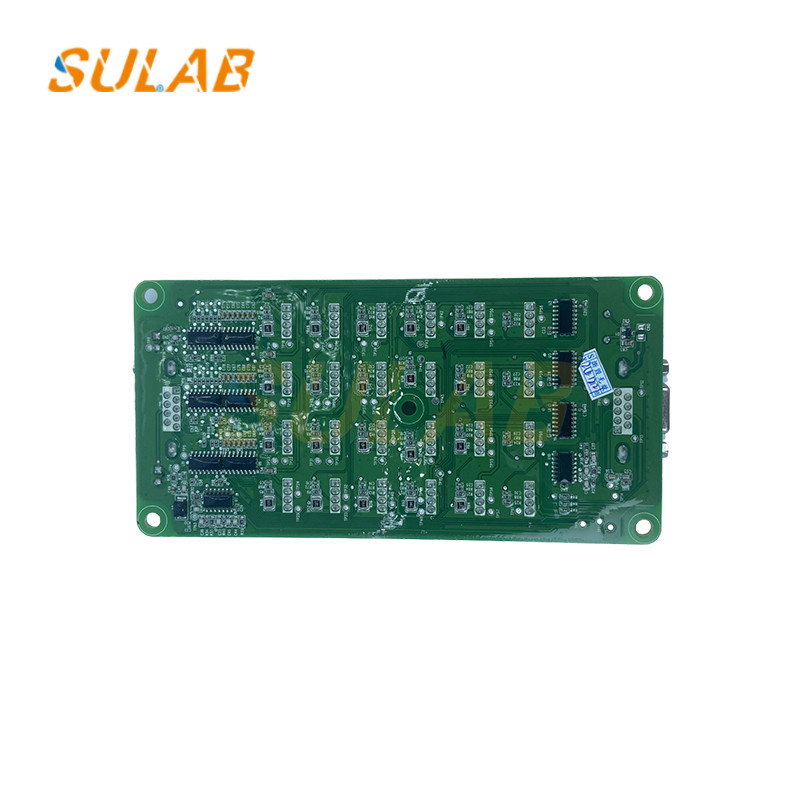

Manufacturing Specifications

-

PCB Type: Multi-layer (likely 4-6 layers) with high-quality FR4 material.

-

Components: SMT (Surface Mount Technology) with industrial-grade ICs, relays, and connectors.

-

Protection: Conformal coating for moisture & dust resistance.

-

Testing: Factory-tested for EMI/EMC compliance and functional validation.

-

-

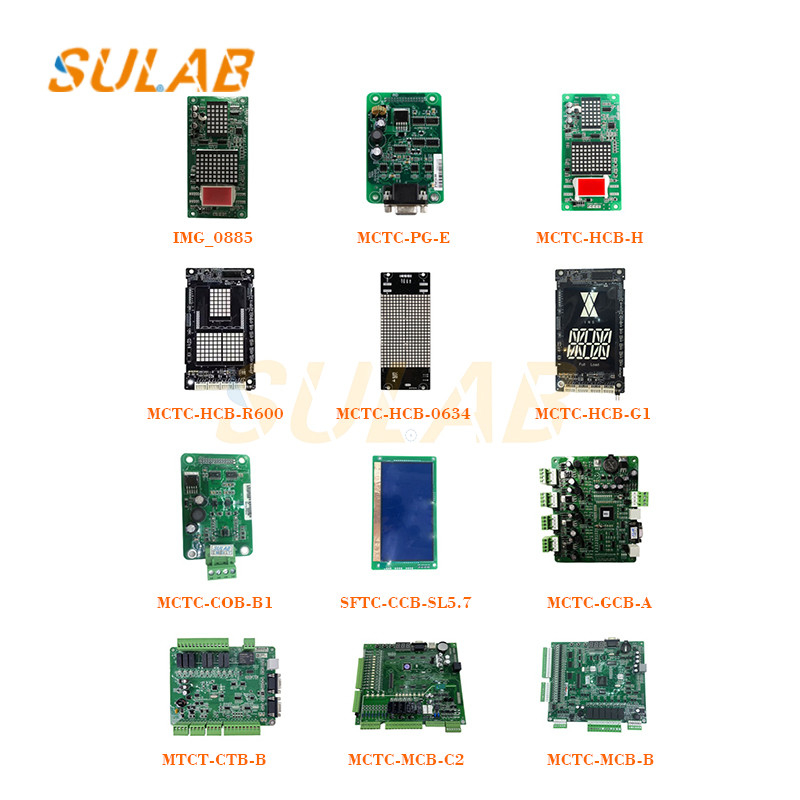

Compatibility & Replacement

-

Designed for Monarch elevator models (specific compatibility should be verified).

-

May require firmware configuration when replaced.

-

-

Common Use Cases

-

Elevator modernization retrofits.

-

Troubleshooting faulty control systems.

-

Spare part replacement in Monarch elevator maintenance.

-