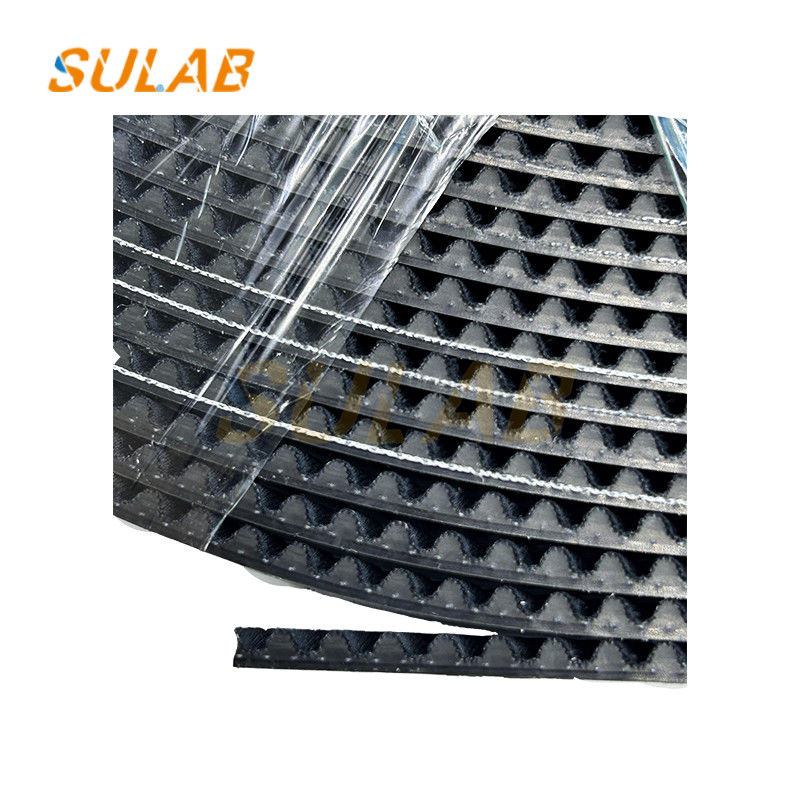

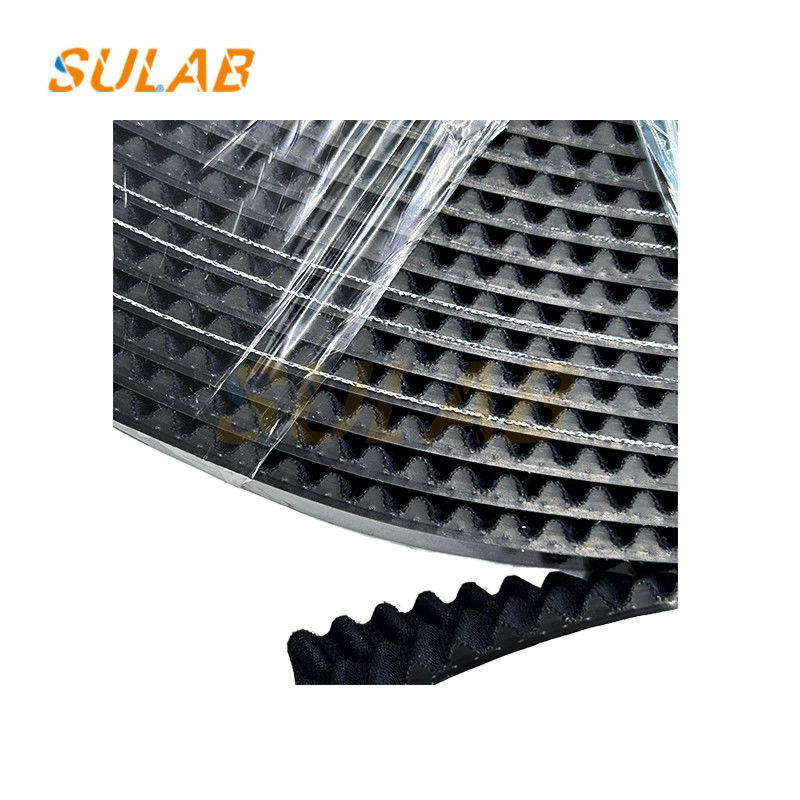

Door Belt for Elevator Parts Elevator Door Motor Door Machine Belt Herringbone Toothed Belt

-

Highlight

Elevator Door Motor Door Belt

,Elevator Parts Door Belt

,Elevator Herringbone Toothed Door Belt

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelHerringbone Toothed Belt

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model NumberHerringbone Toothed Belt

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 2-3 working days after payment

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

Door Belt for Elevator Parts Elevator Door Motor Door Machine Belt Herringbone Toothed Belt

Door Belt for Elevator Parts Elevator Door Motor Door Machine Belt Herringbone Toothed Belt

Features

High friction: The herringbone pattern or tooth design increases the contact area between the belt and the pulley, and the friction also increases accordingly, which can transmit power more effectively, ensure the smooth opening and closing of the elevator door or the stable operation of the elevator car, and prevent slipping.

Strong wear resistance: This belt is usually made of materials with good wear resistance, such as polyurethane, rubber, etc., and the herringbone structure can disperse pressure and reduce local wear during operation, so it has a long service life and can reduce maintenance and replacement costs.

High transmission efficiency: The tooth shape of the herringbone belt can be closely meshed with the tooth groove of the pulley, the energy loss during the transmission process is small, and the transmission efficiency is high, which helps to improve the overall operation performance and energy saving effect of the elevator.

| Brand | SULAB |

| Description | Elevator parts |

| Model | Herringbone Toothed Belt |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

Maintenance and care

Regular inspection: Regularly check the belt for wear, tension, and whether there are cracks, breaks, and other damage. If the belt is found to be severely worn or damaged, it should be replaced in time to avoid affecting the normal operation of the elevator.

Cleaning and maintenance: Keep the belt clean to avoid dust, oil and other impurities adhering to the belt, which will affect the performance and service life of the belt. You can use a clean cloth to wipe the surface of the belt, but be careful to avoid scratching the belt with sharp tools.

Tension adjustment: Regularly check the tension of the belt and adjust it as needed. If the belt is too loose, it will cause slippage and affect the transmission efficiency; if the belt is too tight, it will increase the load on the belt and bearings and shorten the service life.