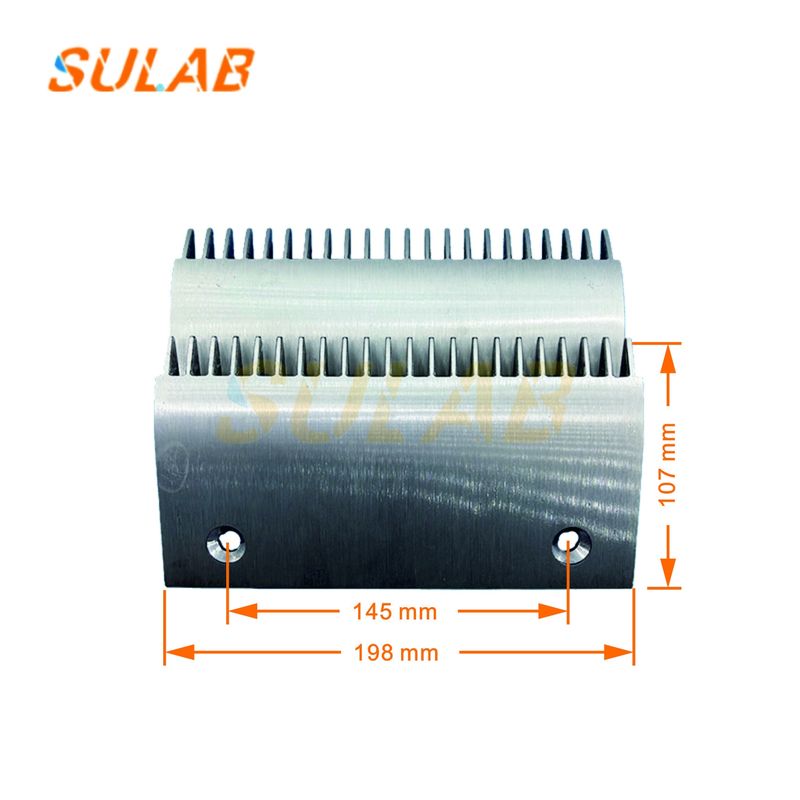

Escalator Sidewalk Aluminum Alloy Comb Plate 22 Teeth Escalator Parts

-

Highlight

Aluminum Alloy Escalator Sidewalk Comb Plate

,Escalator Parts Sidewalk Comb Plate

,22 Teeth Escalator Sidewalk Comb Plate

-

Brand NameSulab

-

Model Number22 Teeth

-

Minimum Order Quantity1

-

Delivery Time5-8working days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

-

Supply Ability1000

Escalator Sidewalk Aluminum Alloy Comb Plate 22 Teeth Escalator Parts

Escalator Sidewalk Aluminum Alloy Comb Plate 22 Teeth Escalator Parts

Key Specifications

-

Material: High-strength aluminum alloy (e.g., 6061-T6 or 6082) for lightweight durability.

-

Dimensions: Customizable to match escalator/sidewalk width (standard lengths: 1000mm, 1200mm, etc.).

-

Teeth Count: 22 precision-machined teeth (compliant with EN 115-1 safety standards).

-

Tooth Pitch: [e.g., 9.6mm or 12.7mm] – Matches step chain roller spacing.

-

Surface Finish: Anodized (standard: silver, black, or custom colors) or powder-coated for corrosion/wear resistance.

-

Load Capacity: Supports dynamic loads up to 150kg per tooth (tested per ISO 4344).

| Brand | Sulab |

| Description | Escalator Aluminum Alloy Comb Plate |

| Model | 22 Teeth |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Escalator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

Material Preparation:

-

-

Aluminum alloy billets cut to size via CNC sawing.

Precision Machining:

-

CNC milling/laser cutting to form 22 teeth with exact pitch/angle (typically 30°–45° tooth angle).

Deburring & Smoothing:

-

Teeth edges polished to eliminate sharpness (R10 radius minimum for safety).

Surface Treatment:

-

Hard anodizing (25–30μm thickness) for abrasion resistance.

-

Optional: Anti-slip coatings or conductive finishes (for static dissipation).

Quality Control:

-

Dimensional inspection (CMM verification of tooth alignment).

-

Load testing (simulated passenger traffic cycles).

-

X-ray inspection (for internal material integrity).

Packaging:

-

Foam-lined wooden crates to prevent transit damage.

-

-

-

-

-

-