Limit Control Permanent Magnet Sensor Elevator Magnetic Switch Sensor Container Induction Switch Relay YG-1A

-

Highlight

Limit Control Elevator Magnetic Switch

,Container Induction Elevator Magnetic Switch

,Permanent Magnet Sensor Elevator Magnetic Switch

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelYG-1A

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model NumberYG-1A

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 2-3 working days after payment

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

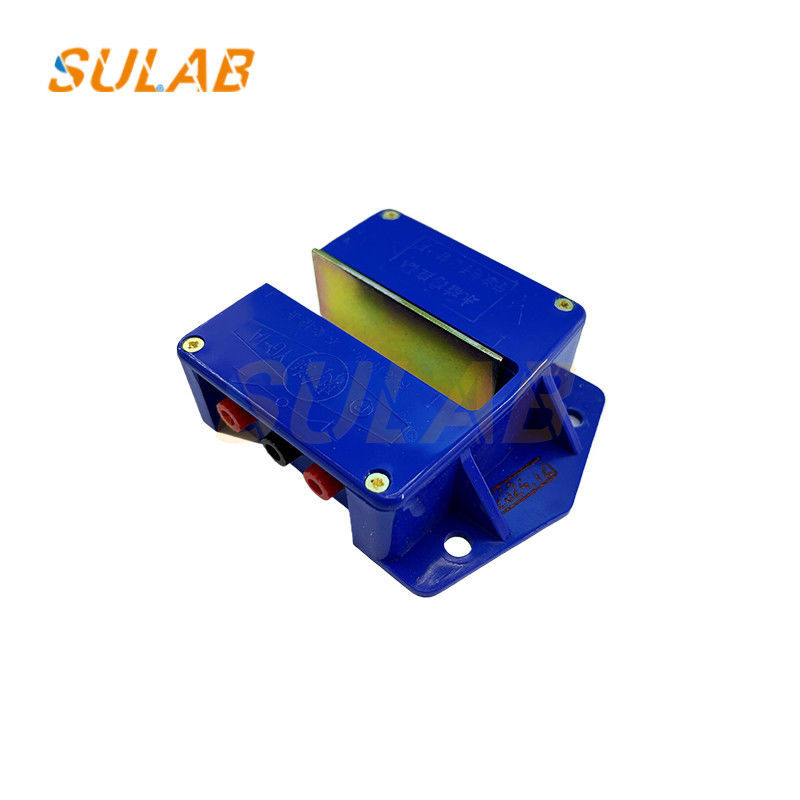

Limit Control Permanent Magnet Sensor Elevator Magnetic Switch Sensor Container Induction Switch Relay YG-1A

Limit Control Permanent Magnet Sensor Elevator Magnetic Switch Sensor Container Induction Switch Relay YG-1A

Features and advantages:

No power supply required: The product contacts use vacuum relays with acid-proof and moisture-proof structures, which can be operated under the action of a magnetic field, without the need for an external power supply, reducing energy consumption and the risk of failure.

Wide applicable voltage range: The contacts can control power supply voltages below DC and AC 380V, with a wide range of applications.

Long mechanical life: The mechanical life of the sensor is <=120,000 times, with high stability and reliability.

| Brand | SULAB |

| Description | Elevator parts |

| Model | YG-1A |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

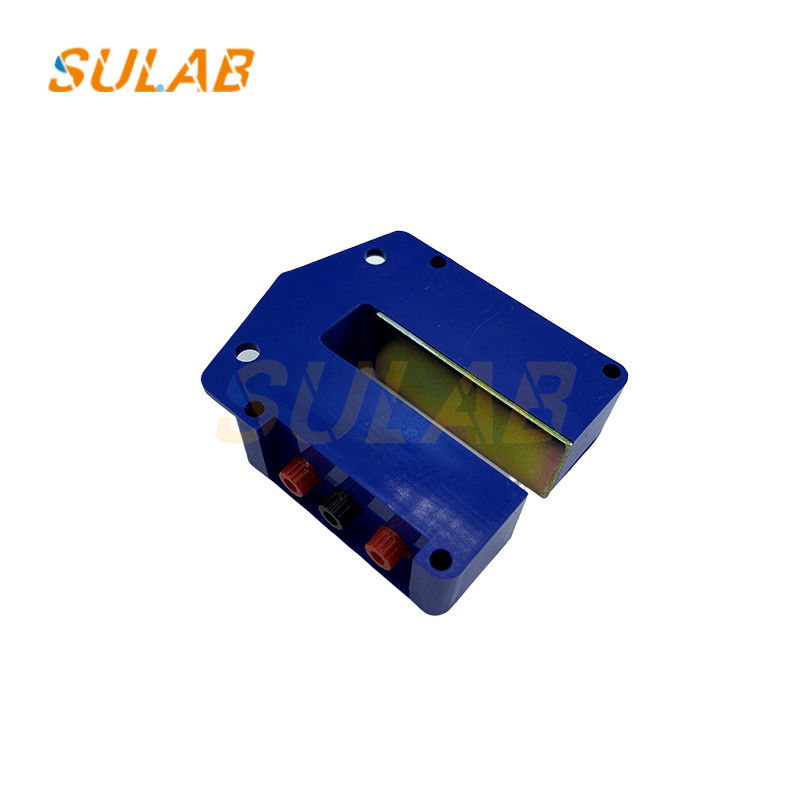

Installation and maintenance: During installation, the YG-1A sensor must be accurately installed at the designated position of the elevator car or guide rail to ensure that its relative position to the permanent magnet is accurate to ensure the accuracy of the induction. In daily maintenance, it is necessary to regularly check whether the sensor is installed loosely, whether there is dust or debris on the surface that affects the induction effect, and whether the contact is working properly.

Application scenarios: Mainly used in various types of elevators, including passenger elevators, freight elevators, medical elevators, etc., to achieve precise leveling control of the elevator, ensure that the elevator can stop accurately when it reaches the target floor, and facilitate passengers to enter and exit the elevator.