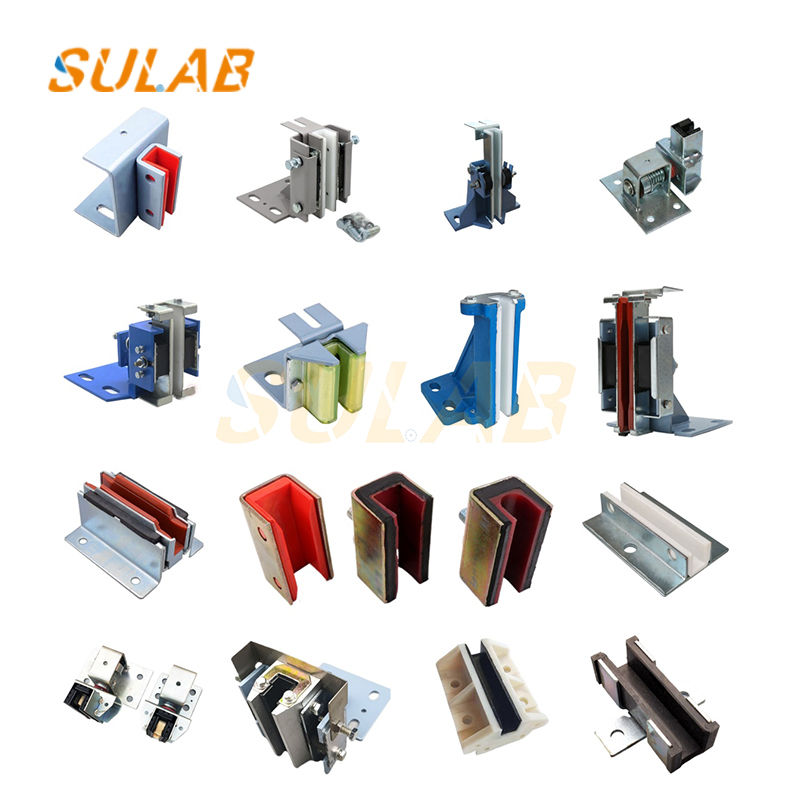

High Quality New Elevator Counterweight Guide Shoe Liner Guide Rail Guide Shoe Counterweight Guide Shoe

-

Highlight

New Elevator Counterweight Guide Shoe

,Rail Elevator Guide Shoe Liner

,New Elevator Guide Shoe Liner

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelCounterweight Guide Shoe

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model NumberCounterweight Guide Shoe

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 2-3 working days after payment

-

Payment TermsL/C,D/P,T/T,D/A,Western Union,MoneyGram

High Quality New Elevator Counterweight Guide Shoe Liner Guide Rail Guide Shoe Counterweight Guide Shoe

High Quality New Elevator Counterweight Guide Shoe Liner Guide Rail Guide Shoe Counterweight Guide Shoe

Structural composition

Fixed seat: used to connect the counterweight frame, generally equipped with a bottom plate, a shoe lining fixing frame, etc. The bottom plate can be a U-shaped bottom plate, which is provided with threaded holes and a support frame for connecting the counterweight frame. The shoe lining fixing frame is welded to the bottom plate and used to fix the shoe lining.

Shoe lining: usually made of nylon or polyurethane material with good wear resistance and shock absorption, its shape and size match the guide rail, the shoe lining sleeve plate is sleeved on the shoe lining fixing frame, and some shoe liners are also provided with a blocking plate to isolate adjacent rubber springs.

Connector: used to fix the shoe lining and the shoe lining fixing frame, with a nail running through the shoe lining fixing frame, a fitting part that fits with the shoe lining sleeve plate, and a stopper for fixing.

| Brand | SULAB |

| Description | Elevator parts |

| Model | Counterweight Guide Shoe |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

Working Principle

Sliding friction principle: The shoe lining of the sliding guide shoe is in direct contact with the surface of the guide rail. When the counterweight moves up and down, the shoe lining slides along the guide rail, and the friction between the shoe lining and the guide rail is used to limit the movement trajectory of the counterweight, so that it can keep running stably on the guide rail.

Elastic buffer principle: The spring or rubber spring in the elastic sliding guide shoe plays a role in buffering and shock absorption. When the counterweight is subjected to vibration or impact during operation, the spring or rubber spring will undergo elastic deformation, absorb and alleviate these energies, reduce the shaking and impact of the counterweight, and make the operation smoother.

Rolling friction principle: The rolling guide shoe uses a roller to replace the shoe lining of the sliding guide shoe. The roller contacts the front and two sides of the guide rail under the action of the spring force and adheres to it. When the counterweight is running, the roller rolls on the guide rail, replacing sliding friction with rolling friction, reducing friction loss, and reducing vibration and noise during operation.