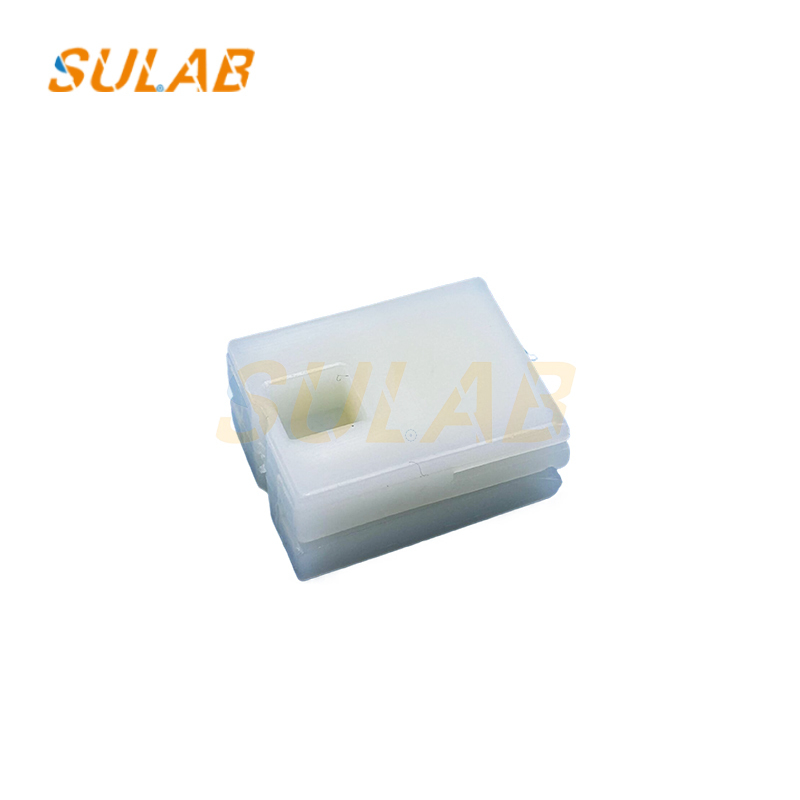

SULAB Elevator Door Slide Rail Guide Slider Wear-resistant Linear Motion

-

Highlight

elevator door slide rail

,wear-resistant linear motion guide

,elevator guide slider with warranty

-

ItemElevator Parts

-

BrandSULAB

-

ModelSlider

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 3-5working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal, Personal Bank Etc

-

Brand NameSULAB

-

Model Numberslider

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 3-5working days after payment

-

Payment TermsL/C,D/P,D/A,T/T,Western Union,MoneyGram

SULAB Elevator Door Slide Rail Guide Slider Wear-resistant Linear Motion

Factory direct sales wear-resistant elevator door slide rail guide slider linear motion suitable for elevator universal elevator door components slider

Location and Function: Installed at the bottom or top of the elevator door leaf, it is a key component connecting the door leaf and the guide rail. Its primary function is to support the door and guide it smoothly during opening and closing, ensuring accurate sliding along the guide rail to avoid jamming, shaking, or misalignment.

Working Principle: By sliding in conjunction with the recessed grooves in the sill or guide rail, the elevator floor and car doors slide horizontally. As the elevator door opens or closes, the slider moves along the guide rail or sill groove, limiting the movement of the door leaf perpendicular to the direction of the door leaf and providing guidance for opening and closing.

Causes of Damage:

Wear: Frequent opening and closing operations cause constant friction between the slider surface and the guide rail, gradually wearing away the surface material, increasing roughness and friction.

Aging: Over time, the slider material ages, degrading performance, and developing deformation, cracks, and other problems.

Insufficient Lubrication: Lack of regular maintenance can cause the lubricant on the slider surface to dry out or become lost, exacerbating wear. Improper installation: Failure to properly align or tighten the slider during installation can result in uneven force on the slider during operation, making it susceptible to damage.

External factors, such as foreign matter intrusion and corrosive environments, can also affect the slider's proper operation.

| Item | Elevator parts |

| Brand | SULAB |

| Model | slider |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 3-5working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal, Personal bank etc |

Maintenance and Care

Regular Inspection: Arrange for professional inspection of the elevator sliders to check for signs of wear, deformation, cracks, and other damage. Measure the clearance between the sliders and guide rails to ensure it is within the specified range.

Cleaning and Lubrication: Regularly clean the sliders and guide rails of dust, oil, and other debris to keep the surfaces clean. Lubricate the sliders with an appropriate amount of lubricant or grease according to the prescribed cycle and method to reduce friction.

Timely Replacement: If a slider is found to be severely damaged, it should be promptly replaced with a new one. Select reliable quality sliders that meet the requirements of the elevator model and have them installed by a professional.