-

Highlight

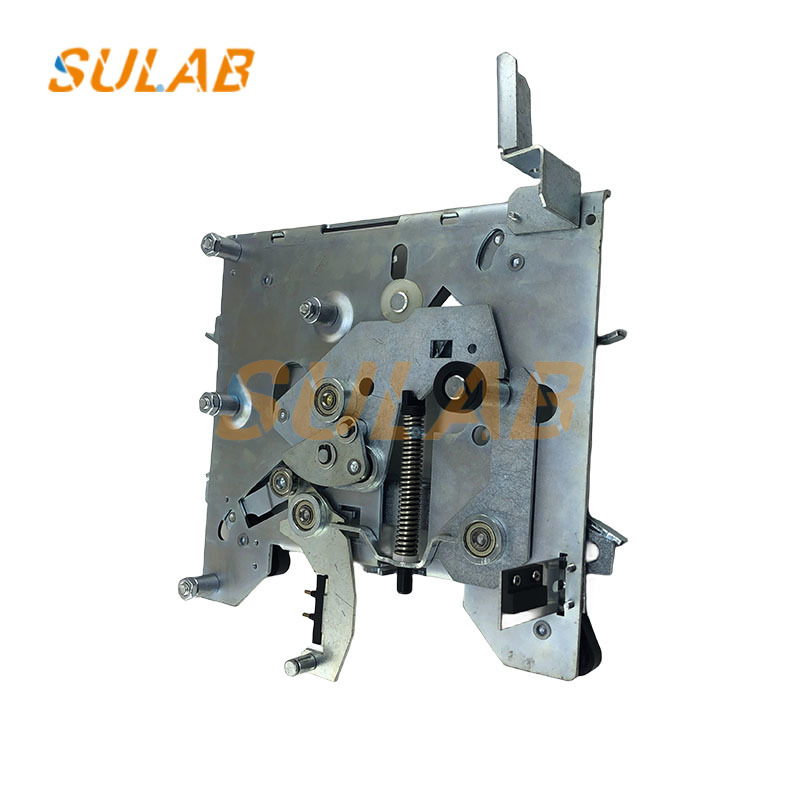

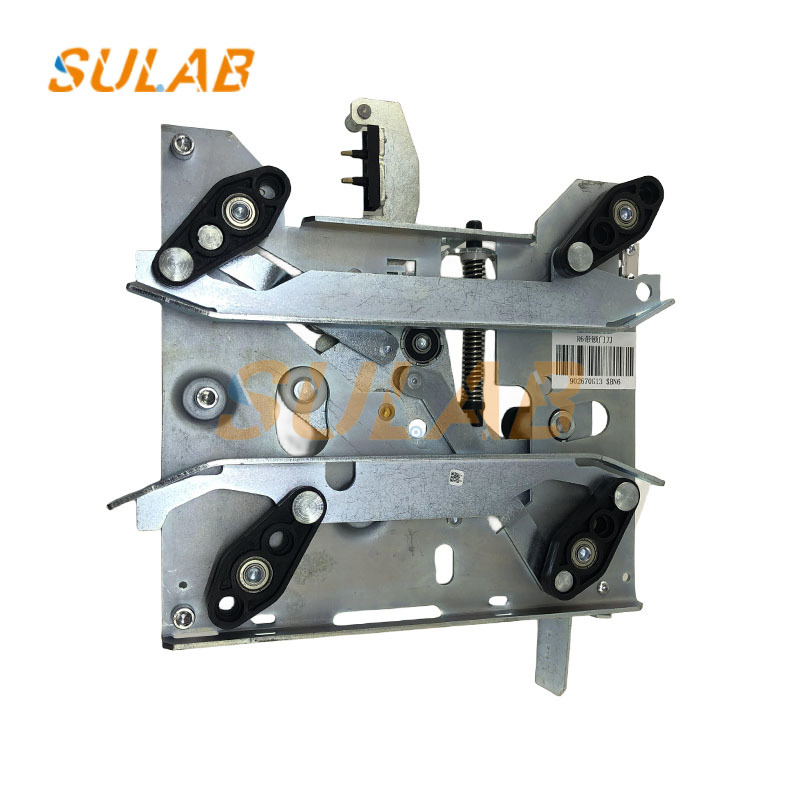

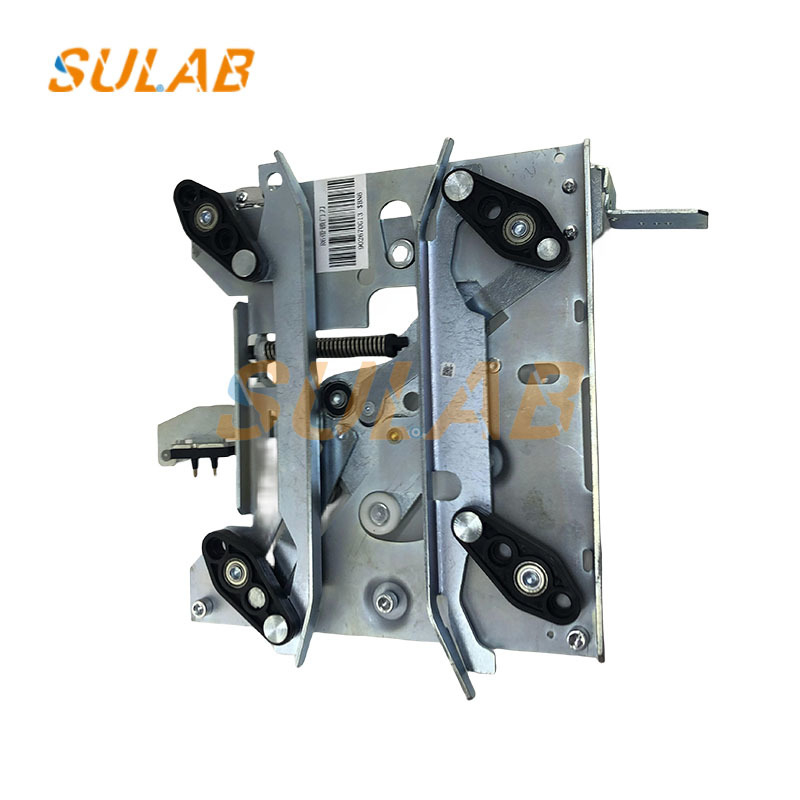

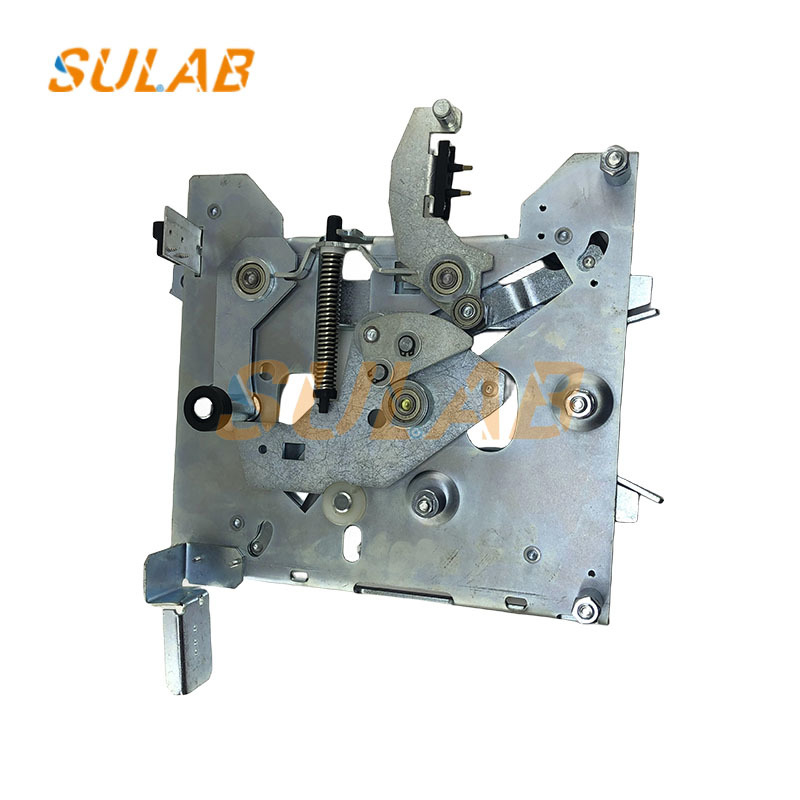

SULAB R6 elevator door knife

,elevator door lock knife

,902670G13 elevator spare part

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelR6 Door Knife With Lock 902670G13

-

MOQ1PC

-

TransportionElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model NumberR6 door knife with lock 902670G13

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 2-3 working days after payment

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

SULAB R6 Elevator Door Knife with Lock 902670G13

Elevator door knife door short knife with lock door knife elevator accessories door knife R6 door knife with lock 902670G13

Installation Process

Pre-installation Preparation: Review the installation instructions and other technical documentation provided by the elevator manufacturer. Confirm that the on-site conditions, including the hoistway and machine room, meet the requirements. Prepare tools and equipment such as an electric drill, torque wrench, laser level, and steel ruler. Installers must hold a special equipment operator certificate.

Door Operator Installation: Secure the door operator to the top of the elevator car, ensuring the horizontal deviation of the door operator's guide rails is ≤0.5mm.

Door Knife Installation: Remove the old door knife (if replacing it) and install the new one in the designated location, usually below the elevator door operator. Secure it securely with bolts and other fasteners, ensuring the required tightening torque. During installation, check that the fan-shaped cam on the back of the door knife is acting on the center position of the bearing. If the cam is misaligned, replace the door knife.

Clearance Adjustment: Adjust the clearance between the door knife and the landing door sill to ensure a clearance of ≥5mm, and the clearance between the door knife and the landing door roller to ensure a clearance of ≥3mm. Close the hall door and check the contact between the door panel and the rubber cushion. If one side of the door panel is not close to the cushion, loosen the tension bolt on the linkage wire rope, adjust the door panel, and then tighten it. Also, ensure the clearance between the lock hook and the latch meets the requirements. This can usually be achieved by adjusting the position of the rubber cushion.

Door lock connection: Ensure the door blade is properly connected to the car door lock to ensure that the door blade reliably opens and closes the door. The connection should be secure and flexible.

| Brand | SULAB |

| Description | Elevator parts |

| Model | R6 door knife with lock 902670G13 |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

Commissioning Process

Checking Automatic Blade Reset: Press and hold the door close button to open the door blade to its maximum width. Manually push the door blade to its limit position, release the door close button, and then slowly release the pressure on the blade to check whether the blade automatically resets. If it does not, install a door blade stop bracket.

Adjusting Blade Spacing: After installing the stop bracket, check the blade spacing when the door blade is open. It should be 107-108mm. If the distance is greater than 108mm, install adjustment shims on the back of the bracket to ensure the required blade spacing.

Debugging Door Operator Functions: Manually debug the door control to check for smooth opening and closing of the door and for no slamming when closing. If any anomalies are detected, adjust the door operator's parameters, such as creep speed or deceleration time.

Debugging Door Lock Coordination: Open and close the door multiple times to observe the coordination between the door blade and the door lock. Ensure that the door blade accurately inserts between the door lock rollers, allows for smooth opening and closing, and that the door lock is secure and reliable when locked. Also, check that the height of the door lock hook and other related dimensions meet the requirements. Overall operation test: During the elevator maintenance and express operation debugging phase, observe the status of the door knife during operation, including whether the door knife moves normally when opening and closing the door, whether it cooperates well with the door locks of each floor, and whether there is any jamming or abnormal noise. It is also necessary to confirm that the door knife does not interfere with other components during operation.