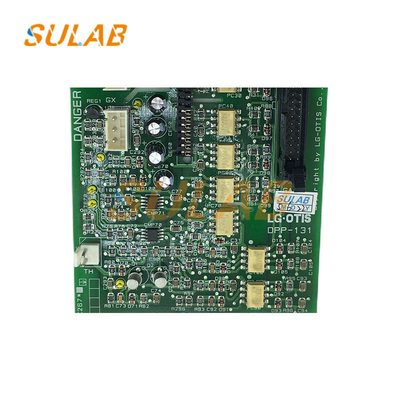

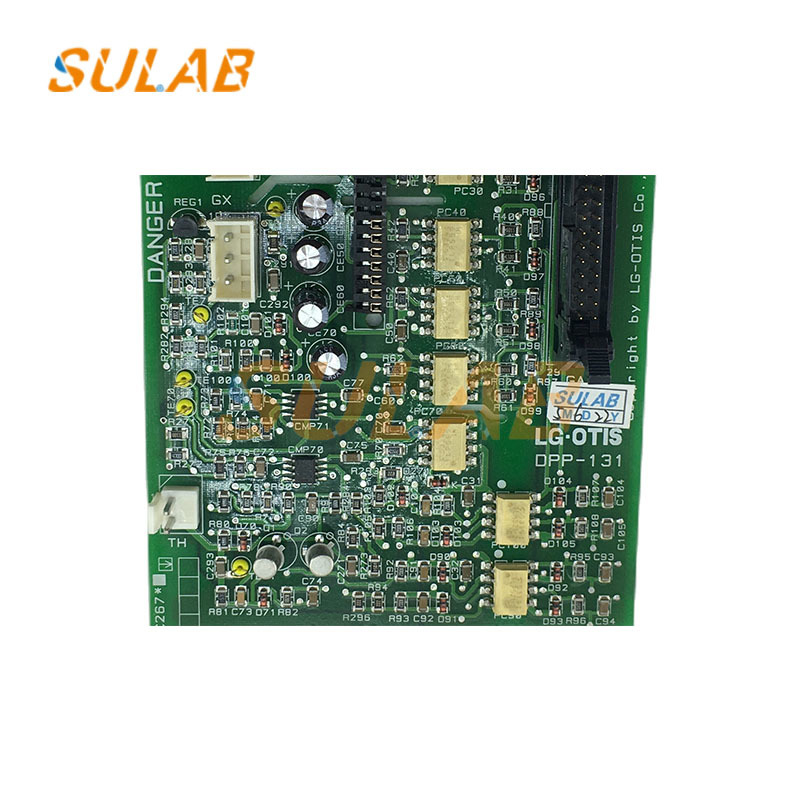

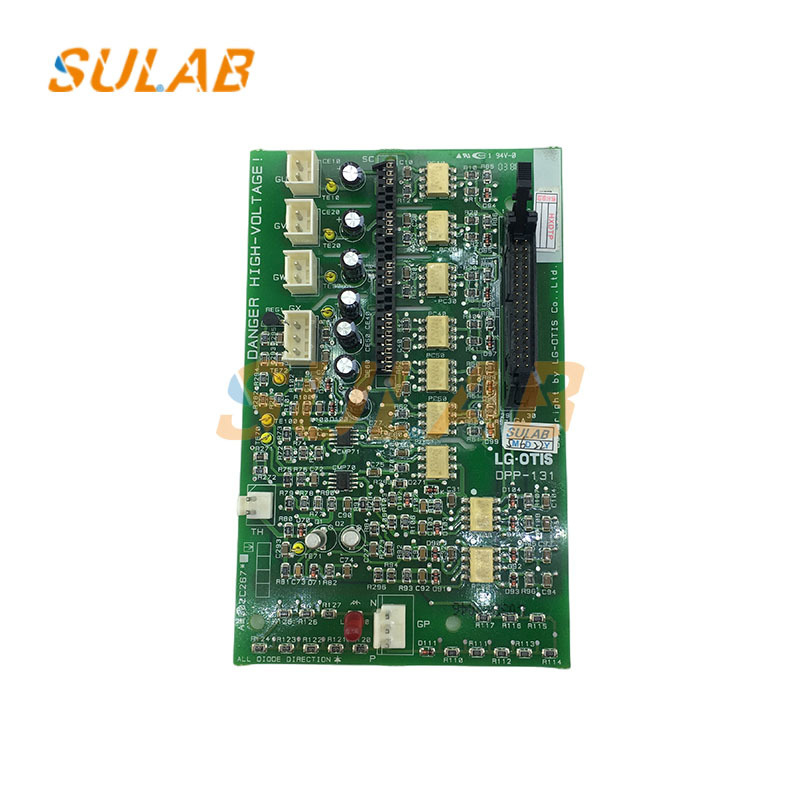

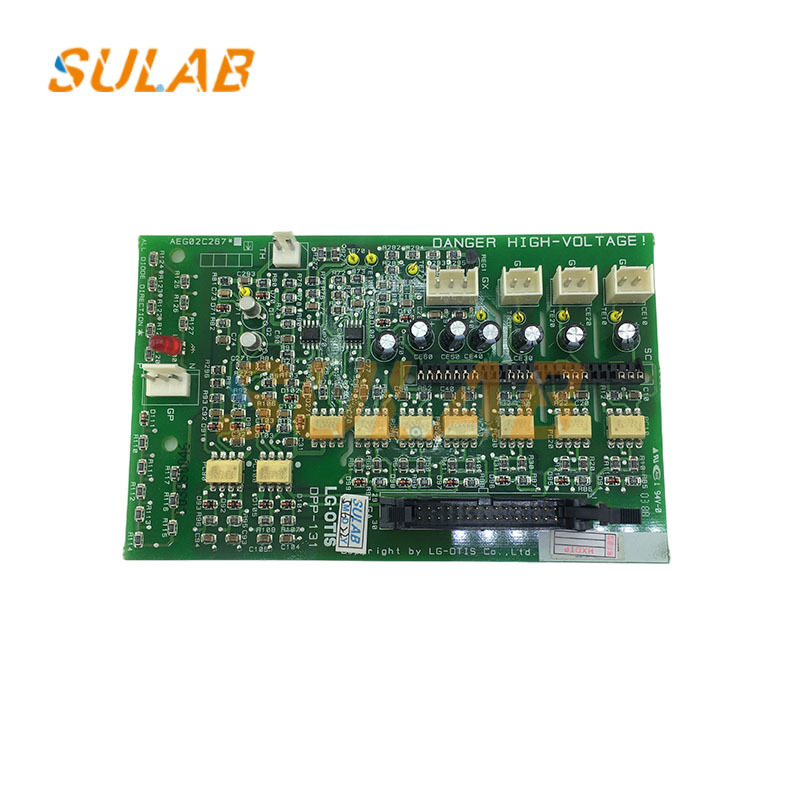

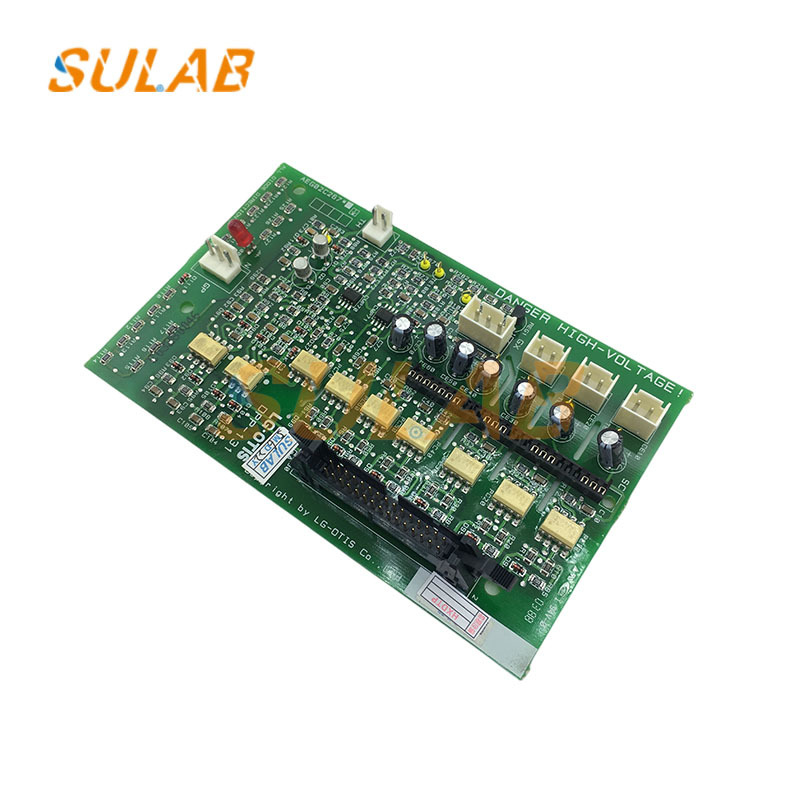

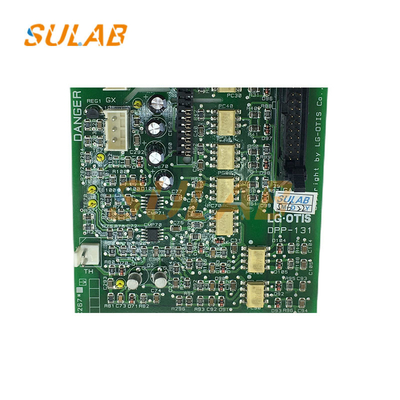

SULAB Elevator Driver Board DPP-131 AEG02C267 for Door Motor Control

-

Highlight

SULAB elevator driver board

,DPP-131 AEG02C267 motor control

,elevator door motor driver

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelDPP-131 AEG02C267

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model NumberDPP-131 AEG02C267

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 2-3 working days after payment

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

SULAB Elevator Driver Board DPP-131 AEG02C267 for Door Motor Control

SIGM elevator motherboard elevator accessories driver board LG elevator module driver board SIGMA PCB elevator module driver board DPP-131 AEG02C267

Door Motor Operation Control

Receives "open/close" commands from the elevator mainboard (such as the DOC-132 mainboard mentioned above) to drive the door motor in forward and reverse rotation, ensuring smooth opening and closing of the car door and landing door.

Supports staged door motor speed adjustment: acceleration during the initial opening/closing phase, constant speed during the intermediate phase, and deceleration nearing the final position, preventing impact with the door and reducing operating noise.

Safety Protection

Anti-pinch protection linkage: Receives signals from the door motor light curtain (such as the Otis light curtain) and the safety touch panel. If an obstacle (such as a person or object) is detected during the door closing process, the door motor immediately reverses and opens the door to prevent pinching.

Overcurrent/overload protection: If the door motor is stuck (such as due to a deformed door track or foreign objects stuck in the door), causing excessive current, the control board will cut off power to the motor to prevent motor burnout or damage to the control board.

Door arrival detection: The door motor position sensor (such as a photoelectric switch or encoder) detects the fully open/closed state of the door and feeds back a signal to the elevator mainboard, ensuring the elevator does not start if the door is not fully closed. Signal Interaction and Status Feedback

Interacts with the elevator mainboard (e.g., DOC-132) via a communication bus (e.g., RS485, dedicated door operator communication line): Sends status information such as "door fully open/closed" and "door fault," and receives commands such as "forced door open/close" and "door operator speed parameters."

Built-in indicator lights (e.g., power, operation, and fault) provide intuitive feedback on the control board's operating status (e.g., the fault light will be solid or flashing in the event of a fault).

| Brand | SULAB |

| Description | Elevator parts |

| Model | DPP-131 AEG02C267 |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

Pre-Installation Preparation

Safety Precautions: Disconnect the elevator's main power supply and the door operator's power supply. Hang a "Do Not Operate" warning sign. Wear an anti-static wrist strap to prevent static electricity from damaging the control board chip.

Compatibility Verification: Confirm that the control board model (DPP-131 AEG02C267) matches the door operator motor model and the elevator mainboard (e.g., DOC-132) to avoid malfunctions due to model incompatibility.

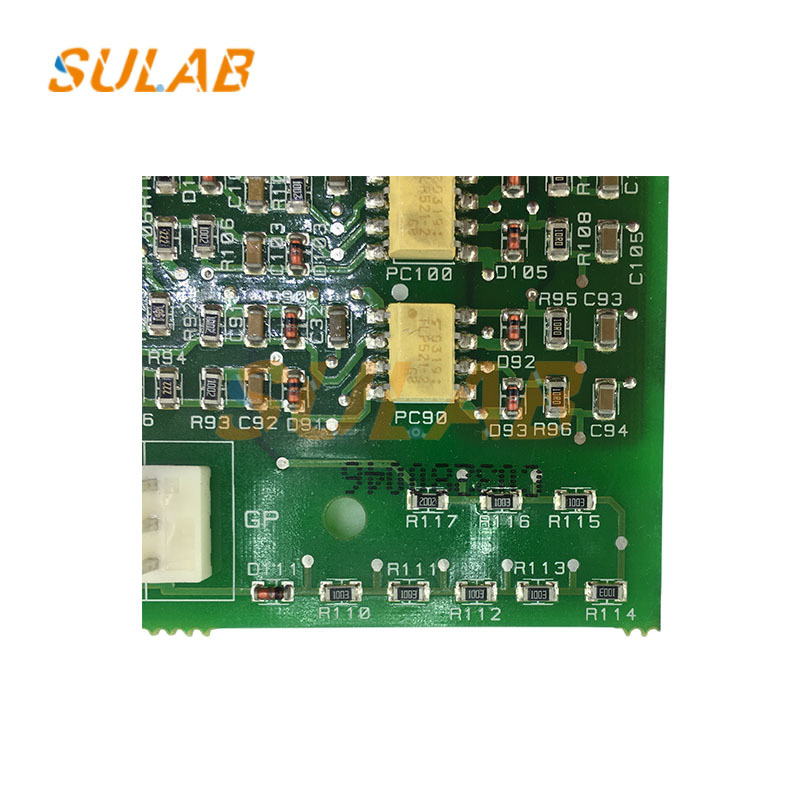

Appearance Inspection: Check that the control board is free of physical damage (such as chip loss, capacitor swelling, or oxidized terminals) and that the door operator motor cables are free of damage.

Installation Procedures

Securing the Control Board: Install the control board onto the bracket provided in the door operator box and secure with the provided screws (torque 3-5 N·m; avoid overtightening to avoid damaging the PCB). Ensure that the heat dissipation holes are not blocked.