High-Quality Siemens Elevator Contactor 3RT1026-1B with AC-3 25A/400V Rating for Motor Overload Protection and Remote Control

-

Highlight

AC-3 25A/400V Elevator Contactor

,Motor Overload Protection Siemens Contactor

,Remote Control 3RT1026-1B

-

BrandSULAB

-

DescriptionElevator Parts

-

Model3RT1026-1B

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model Number3RT1026-1B

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 2-3 working days after payment

-

Payment TermsL/C,D/A,D/P,T/T,Western Union

High-Quality Siemens Elevator Contactor 3RT1026-1B with AC-3 25A/400V Rating for Motor Overload Protection and Remote Control

High-quality new contactors Siemens elevator control components elevator contactors 3RT1026-1B

General Industrial Core Functions:

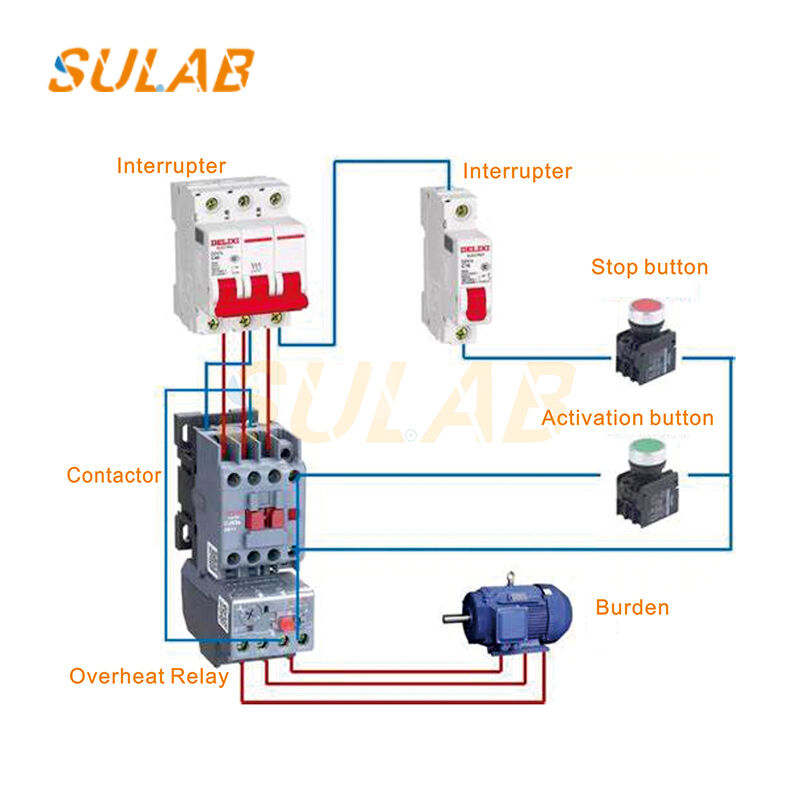

When the load on/off control coil is energized, electromagnetic attraction causes the contacts to close, connecting the main circuit and allowing the load (such as a motor or heater) to operate. When the coil is de-energized, the spring returns the contacts to open, stopping the load. The main contacts support rated loads of AC-3 25A / 400V (11kW motor), meeting the start-stop requirements of most small and medium power motors.

Circuit Isolation and Protection: When the auxiliary contacts are open, the main circuit and control circuit are electrically isolated, preventing control-side faults from affecting the main circuit. It can also be used with a thermal overload relay (such as 3RU1126) to provide overload protection for the motor. When the motor is overloaded, the thermal relay triggers the contactor coil to de-energize, cutting off the main circuit.

Remote and Automatic Control: The coil can be driven by control elements such as buttons, PLCs, and relays to achieve remote manual or automatic program control without direct operation of high-voltage components in the main circuit, improving operational safety.

| Brand | SULAB |

| Description | Elevator parts |

| Model | 3RT1026-1B |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

The door operator system control is used for the start and stop control of the elevator car door/landing door drive motor. It receives signals from the door operator controller and controls the door operator motor to operate (open/close) or stop when powered off. It is the core actuator for door operator operation.

The brake circuit control uses this contactor in the elevator's brake coil power supply circuit. When the elevator needs to run, the contactor closes, energizing the brake coil to release the brake; when the elevator stops, the contactor opens, de-energizing the brake coil and locking the brake to ensure safe elevator stopping.

Auxiliary load control is used for the on/off control of small and medium power loads such as fans, lighting, and brake auxiliary power supplies within the elevator control cabinet, enabling automatic start and stop of these auxiliary devices (e.g., fans start when the elevator is running and stop when in standby mode).

Drive circuit auxiliary control, in the front or back circuits of some elevator inverters, can serve as an actuator for power switching or bypass control, working with the control system to implement the inverter's start and stop logic.