Mitsubishi Elevator Traction Sheave Permanent Magnet All Size Made of Ductile Iron QT600-3

-

Highlight

Permanent Magnet Elevator Traction Sheave

,All Size Elevator Traction Sheave

,Ductile Iron QT600-3 Elevator Sheave

-

BrandSulab

-

DescriptionElevator Elevator Traction Sheave

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSulab

-

Model NumberAll size

-

Minimum Order Quantity1

-

Delivery Time2-3 working days

-

Payment TermsD/P,T/T,Western Union

Mitsubishi Elevator Traction Sheave Permanent Magnet All Size Made of Ductile Iron QT600-3

Mitsubishi Elevator Traction Sheave Permanent Magnet All Size

Mitsubishi Elevator Traction Sheave Permanent Magnet All Size

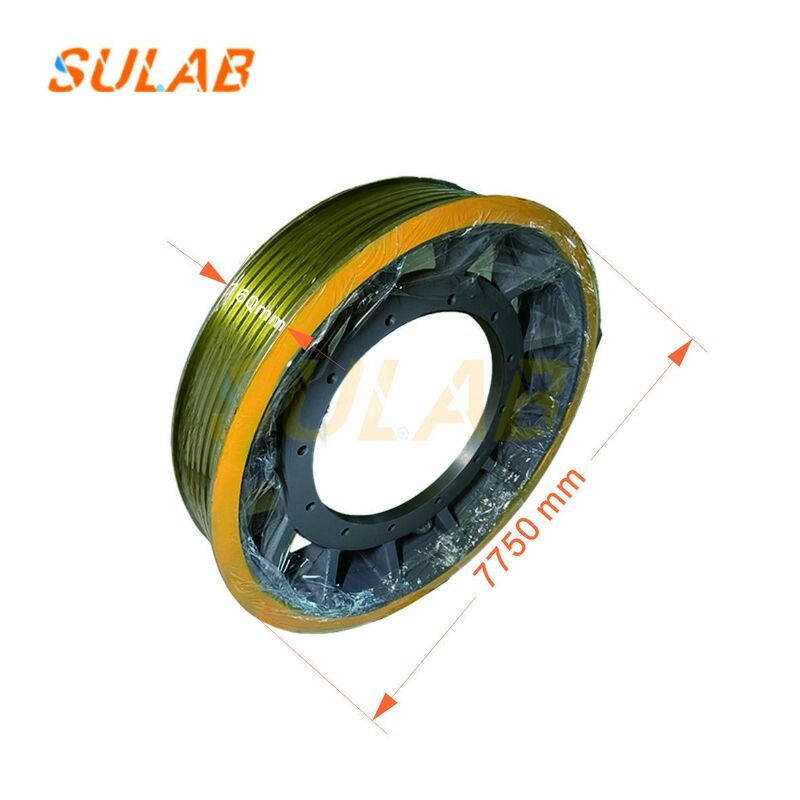

The traction sheave serves as the core component of elevator traction machines, enabling car lifting through friction between steel wire rope and car/counterweight systems. Mitsubishi traction sheaves are available in two primary configurations: geared models for early GPS series and permanent magnet synchronous gearless models for Lingyun/Lingyun ZPML series and EM series traction machines.

Product Specifications

| Brand | Sulab |

| Description | Elevator Traction Sheave |

| Minimum Order Quantity | 1PC |

| Transportation | TNT, UPS, DHL, Fedex, Air, Sea |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, Alibaba, Paypal etc |

Technical Features

Specification format: "diameter × rope groove pitch × number of rope grooves / shaft hole" (e.g., 400×5×8, 620×6×12)

Compatible with elevator models of varying load capacities and speeds

Material & Construction

Main body constructed from ductile iron QT600-3 for superior strength and impact resistance

Rope groove surface features dual processing options: carburizing quenching with precision grinding OR polyurethane/wear-resistant nylon composite pads

Carburized layer depth: 0.8-1.2mm with surface hardness of HRC58-62

Engineered to minimize steel wire rope wear, extend service life, and prevent slipping

Gearless models utilize integral casting formation with dynamic balance correction (≤0.05g*m)

Protected by oil-resistant epoxy coating for durability in machine room and hoistway environments with oil pollution and humidity