Elevator Control Transformer 260VA 415V with H-class Insulation for Elevator Systems

-

Highlight

260VA Elevator Transformer

,415V Control Transformer

,H-class insulation Elevator Control Transformer

-

BrandSulab

-

DescriptionElevator Transformer

-

ModelTDB-260-16(415V)

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSulab

-

Model NumberTDB-260-16(415V)

-

Minimum Order Quantity1

-

Delivery Time2-3 working days

-

Payment TermsD/P,T/T,Western Union

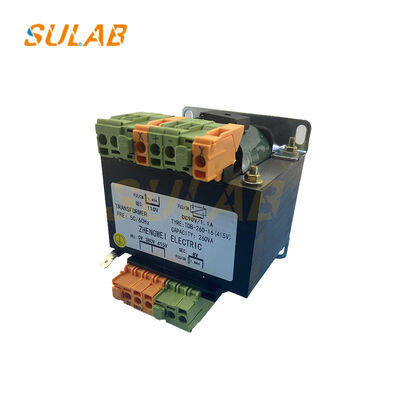

Elevator Control Transformer 260VA 415V with H-class Insulation for Elevator Systems

Elevator Control Transformer - TDB Series

Specialized control transformers designed specifically for elevator applications, available in capacities from 100VA to 450VA including 260VA models.

Product Overview

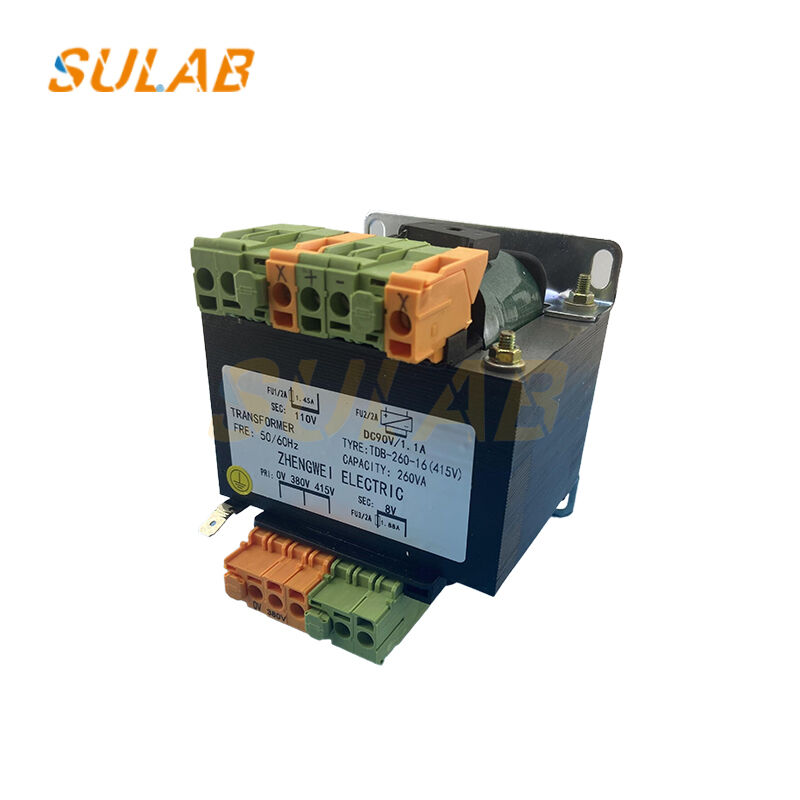

The TDB-260-16(415V) is part of the TDB series of specialized control transformers for elevators. With a rated capacity of 260VA and input voltage of 415V three-phase AC (50/60Hz), this transformer is specifically designed for elevator control cabinets in 415V power supply systems. It provides safety isolated control power for elevator control systems, signal systems, and door machine systems.

Technical Specifications

| Brand | Sulab |

|---|---|

| Description | Elevator Transformer |

| Model | TDB-260-16(415V) |

| Minimum Order Quantity | 1PC |

| Transportation | TNT, UPS, DHL, Fedex, Air, Sea |

| Packaging | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, Alibaba, Paypal etc |

Key Features & Benefits

- Converts 415V three-phase grid voltage to various low-voltage levels (110V, 24V, 12V) required by elevator control systems

- Electrical isolation between primary and secondary windings with insulation resistance ≥1000MΩ

- Effectively suppresses grid interference and prevents leakage and electric shock risks

- Protects elevator control circuits and ensures personnel safety

- 16 output tap design for flexible configuration of different voltage combinations

- Meets power supply needs for elevator main control boards, call boards, display boards, safety circuits, and door machine controllers

- Voltage regulation rate ≤3% ensures stable output voltage during load changes

- Constructed with low-loss silicon steel sheets and H-class oxygen-free copper wires

- Features flame-retardant frames and terminals with overall vacuum pressure impregnation

- Insulation class H (180℃) with natural cooling method

- Operating temperature range: -10°C to +40°C

- Maximum altitude: ≤1000m with protection class IP20

Compliance & Certification

Complies with GB 19212.1 and EN 61558-2-6 safety standards, featuring CE/CCC certification and backed by a 12-month warranty.