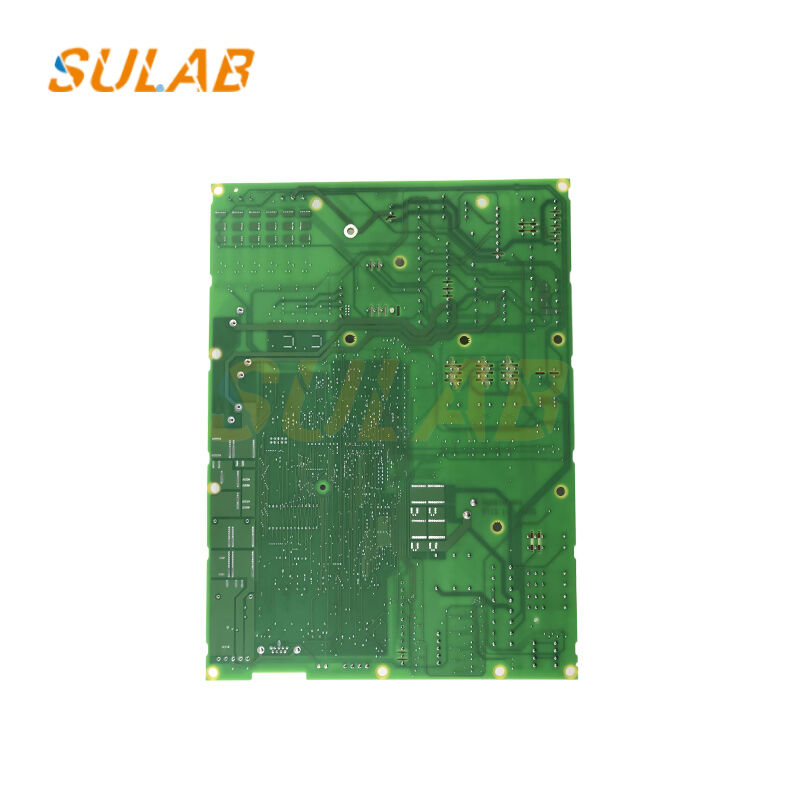

Otis Elevator TCBC Mainboard GDA26800KA1 with 32-bit ARM Processor and CAN Bus Communication EN 81-20/50 Compliant

-

Highlight

32-bit ARM processor Otis Elevator TCBC Mainboard

,CAN bus communication Elevator Control Board

,EN 81-20/50 compliant GDA26800KA1 Mainboard

-

BrandOTIS

-

DescriptionElevator Board

-

ModelGDA26800KA1

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameOTIS

-

Model NumberGDA26800KA1

-

Minimum Order Quantity1

-

Delivery Time2-3 working days

-

Payment TermsD/P,T/T,Western Union

Otis Elevator TCBC Mainboard GDA26800KA1 with 32-bit ARM Processor and CAN Bus Communication EN 81-20/50 Compliant

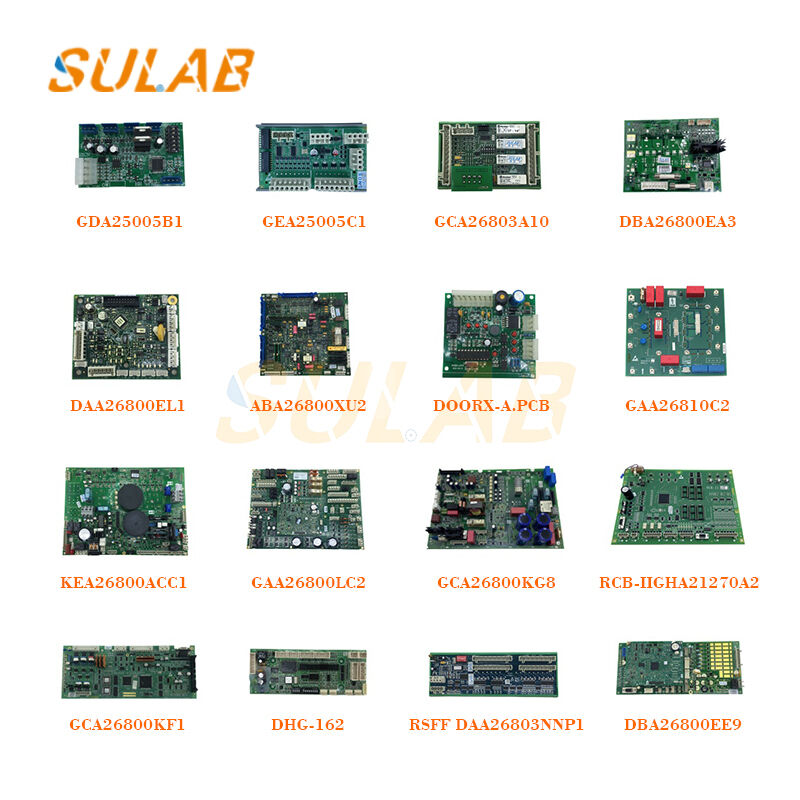

Otis Elevator TCBC Mainboard GCA GDA26800KA1 GDA26800KA2 GAA26800BA2GI

The GDA26800KA1 is Otis TCBC (Traction Control Board Cabinet) mainboard, serving as the core control unit for Otis 406/OVF20CR inverter systems. This advanced control board is compatible with Gen2, SkyRise, OH5100, OH6000 and other elevator series.

Technical Specifications

| Brand | OTIS |

|---|---|

| Description | Elevator Control Board |

| Model | GDA26800KA1 |

| MOQ | 1PC |

| Processor | 32-bit ARM |

| Working Voltage | DC24V(±10%) |

| Communication Interfaces | CAN bus (250kbps), RSL car/hoistway communication, MODBUS RTU |

| Dimensions | 300×220×45mm |

| Mounting | Guide rail mounting (35mm standard guide rail) |

| Protection Class | IP20 |

| Compliance | EN 81-20/50, GB 7588 safety standards |

| Certification | CE/CCC |

| Warranty | 12 months |

Control Capabilities

This mainboard provides comprehensive control over elevator start, operation, stop, acceleration and deceleration processes. Utilizing closed-loop vector control algorithms, it delivers exceptional performance with speed control accuracy of ±0.01m/s and acceleration control accuracy of ±0.05m/s².

- Supports multi-speed operation (up to 16 speeds)

- Suitable for elevator running speed range of 0.5-4.0m/s

- Ensures smooth start-stop transitions and comfortable operation

Input/Output Configuration

The board integrates extensive I/O capabilities for comprehensive elevator monitoring and control:

- 32 digital inputs (DI) for safety circuits and sensor data

- 16 digital outputs (DO) for control commands

- 8 analog inputs (AI) for precision measurements

- 4 analog outputs (AO) for fine-tuned control signals

Real-time data collection includes safety circuit status, door lock circuits, inspection signals, weighing data, and position information. Processed data is transmitted to drive boards via CAN bus for precise elevator control.

Shipping & Payment

| Transportation | TNT, UPS, DHL, Fedex, Air, Sea |

|---|---|

| Packaging | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Payment Methods | Company Bank, Western union, Alibaba, Paypal etc |