Elevator STVF9 Inverter WB100G Encoder Board WBVF Inverter Motherboard WBVF_N

-

Highlight

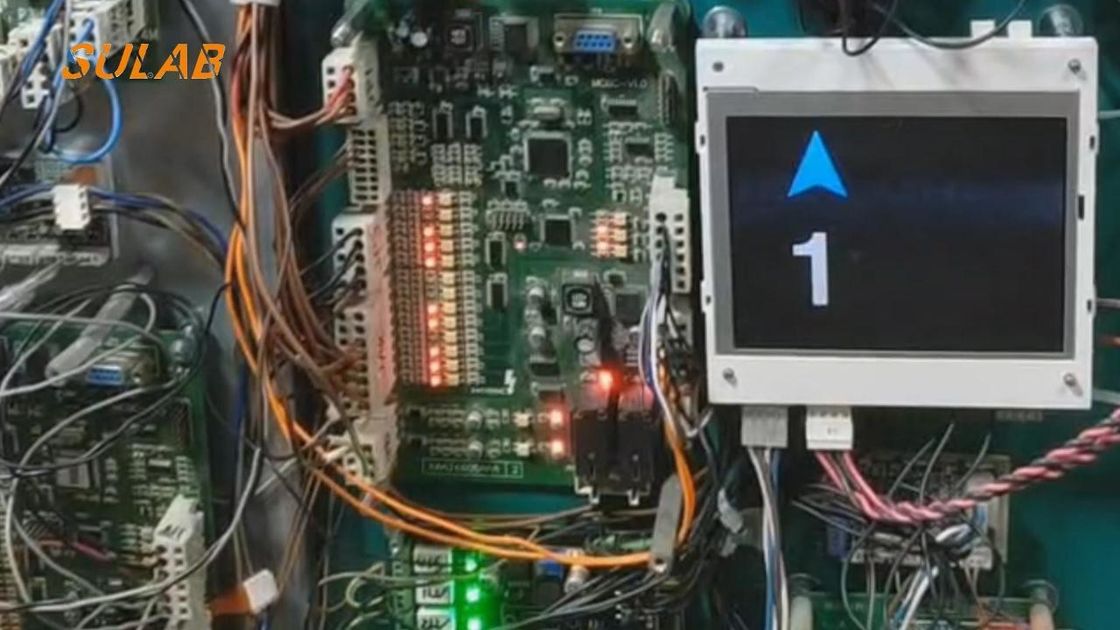

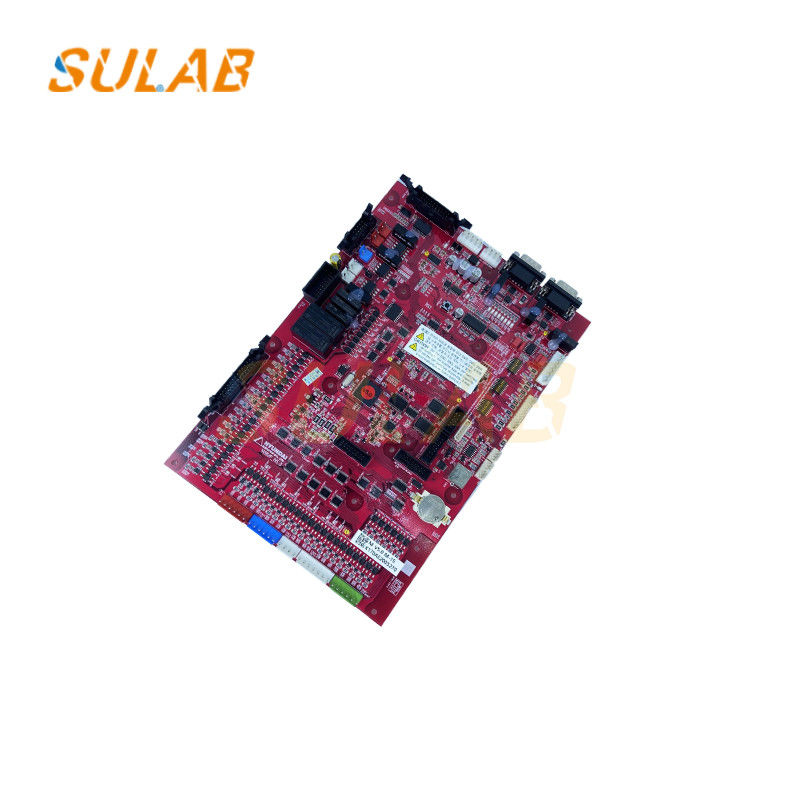

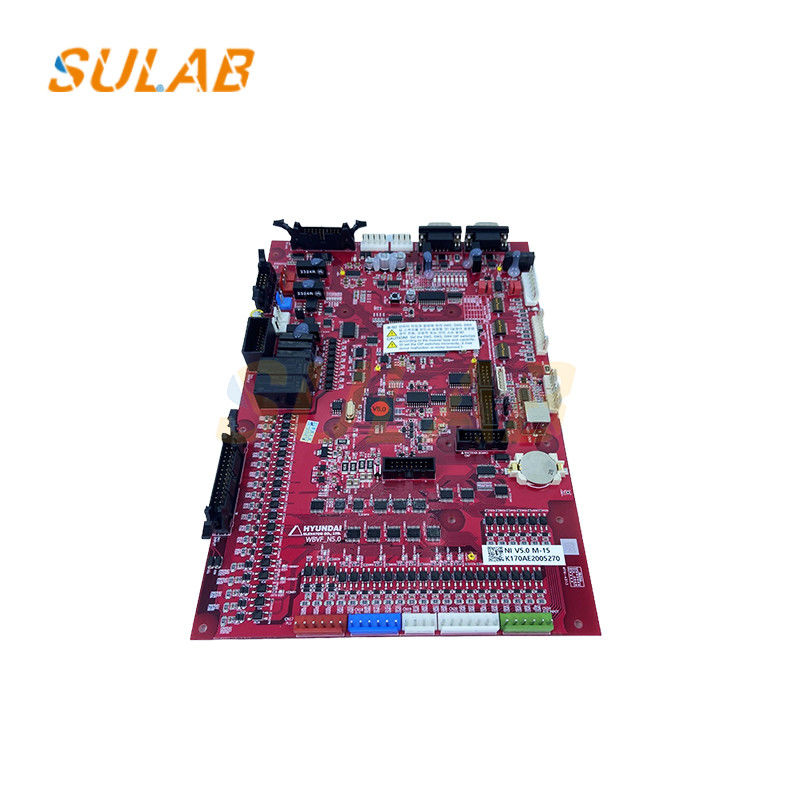

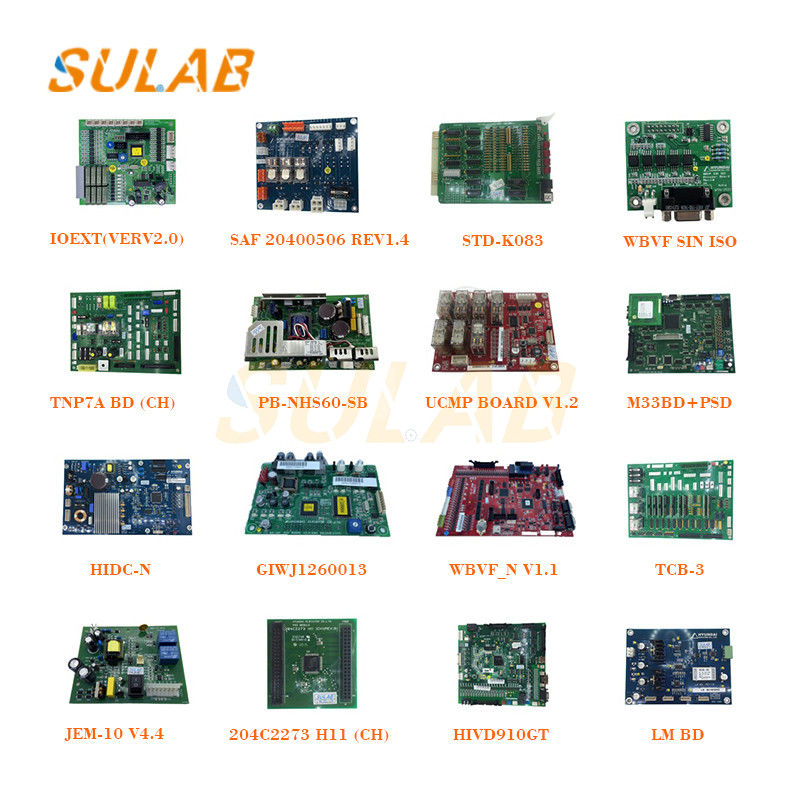

WBVF inverter motherboard

,WB100G encoder board

,Elevator STVF9 inverter

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelWBVF_N

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

DescriptionElevator Parts

-

ModelFB-9B

-

Brand NameSULAB

-

Model NumberWBVF_N

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

Elevator STVF9 Inverter WB100G Encoder Board WBVF Inverter Motherboard WBVF_N

Elevator STVF9 inverter WB100G encoder board WBVF inverter motherboard WBVF_N

Function:

Control function

Control algorithm operation: The mainboard runs various control algorithms, such as vector control, direct torque control, etc., and realizes smooth speed regulation and efficient operation of the motor by accurately controlling the current, voltage, frequency and other parameters of the motor.

Logic control: Process various logic signals and coordinate the work of various parts inside the inverter, such as controlling the switching action sequence of the rectifier and inverter to ensure the normal start, operation and stop of the inverter.

Signal processing function

Analog signal processing: Amplify, filter, and convert analog signals from the outside, such as given speed command signals, feedback motor current and voltage signals, etc., and convert them into digital signals for analysis and processing by the microprocessor on the mainboard.

Digital signal processing: Process digital signals, such as receiving key commands from the operation panel, digital signals communicating with the host computer, etc., to realize various operations and monitoring of the inverter.

Communication function

Communication with external devices: Through various communication interfaces, such as RS485, CAN, Ethernet, etc., communicate with the host computer (such as PLC, industrial computer), other inverters or intelligent devices to achieve remote control, monitoring and data exchange.

Protocol conversion: Support multiple communication protocols, such as Modbus, Profibus, DeviceNet, etc., encapsulate and parse the internal data of the inverter according to the corresponding protocol format, so as to be compatible and communicate with devices from different manufacturers.

Protection function

Overcurrent protection: Monitor the motor current. When the current exceeds the set threshold, the mainboard immediately takes protective measures, such as stopping output and issuing alarm signals, to prevent the motor and inverter from being damaged due to overcurrent.

Overvoltage protection: Detect the DC bus voltage. When the voltage is too high, the protection mechanism is triggered to prevent the electronic components inside the inverter from being damaged due to overvoltage.

Overheat protection: The temperature of key components (such as power modules, heat sinks, etc.) inside the inverter is monitored by temperature sensors. When the temperature exceeds the allowable range, the output power is automatically reduced or the operation is stopped to prevent overheating and damage to the equipment.

Undervoltage protection: When the power supply voltage is lower than the set value, the mainboard will stop the operation of the inverter to protect the equipment from faults caused by undervoltage.

Drive function: The mainboard generates a drive signal, which is amplified by the drive circuit to control the on and off of the power switching devices (such as IGBT) in the inverter, and converts DC power into AC power with adjustable frequency and voltage for use by the motor.

Parameter storage and management function: Store various parameters of the inverter, such as motor parameters, control parameters, protection parameters, etc. These parameters can be set and modified through the operation panel or communication interface. The mainboard can ensure the correct storage and reading of the parameters, and the parameters will not be lost after the inverter is powered off. At the same time, the mainboard can also manage the parameters, such as initializing, backing up and restoring the parameters.

| Brand | SULAB |

| Description | Elevator parts |

| Model | WBVF_N |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |