-

Highlight

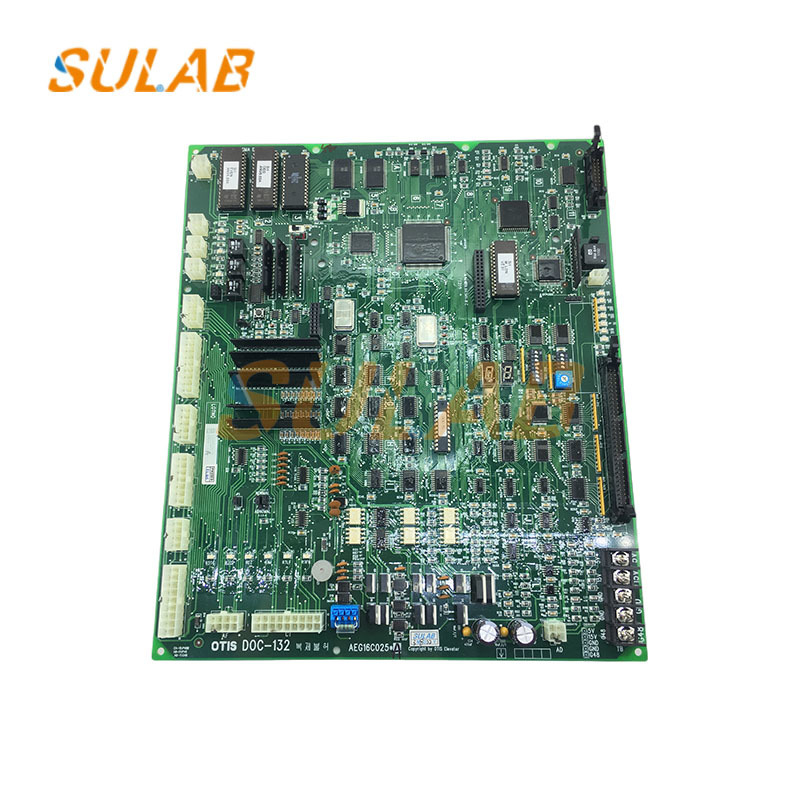

SULAB elevator control board 24V

,DOC-132 elevator PCB board

,AEG16C025A elevator control PCB

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelDOC-132 AEG16C025A

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model NumberDOC-132 AEG16C025A

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 2-3 working days after payment

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

SULAB Elevator Control Board DOC-132 AEG16C025A 24V PCB

Elevator Control Board LG PCB Board Elevator Motherboard High Quality Wholesale Elevator Motherboard DOC-132 AEG16C025A

Basic Information: This motherboard is manufactured in China and is an elevator component. Model number: DOC-132, also known as AEG16C025*A, it is primarily used in residential elevators and other applications.

Functional Features: As the core component of the elevator control system, it performs important functions such as elevator operation control, safety protection, and signal transmission. It enables functions such as floor height measurement, manual LRT operation, POSI test mode, 110% shear mode, and resets CRT data. It may also provide motor overcurrent and overload protection, automatic car lighting and fan control, base station elevator lock, remote elevator lock interface, and car and hall command IC card control.

Common Faults and Symptoms: When this motherboard malfunctions, the elevator may fail to start or frequently stop during operation, command signals may be lost or misrepresented, safety protection devices may not function properly, and the display may display garbled or blank.

| Brand | SULAB |

| Description | Elevator parts |

| Model | DOC-132 AEG16C025A |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

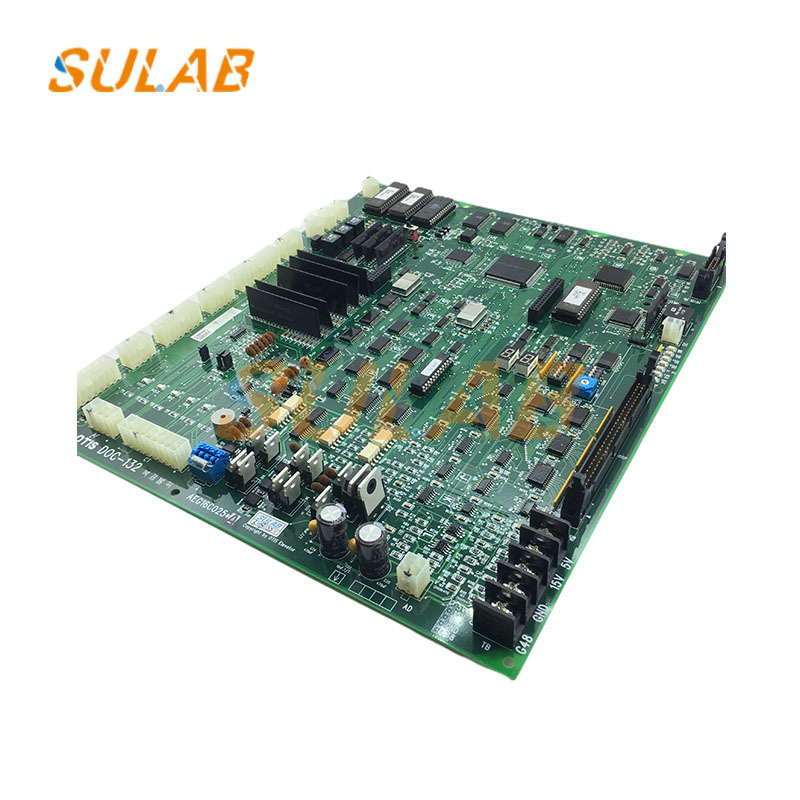

Positioning and securing the motherboard

According to the designated mounting holes in the control cabinet, place the motherboard firmly on the mounting bracket. Ensure that the motherboard connectors (such as the power connector, communication connector, and I/O connector) are oriented for easy wiring and avoid excessive bending of the cables.

Use the provided screws to tighten evenly diagonally (the torque should comply with the manual. Too loose a screw may result in poor contact, while too tight a screw may damage the motherboard PCB). If the mounting surface is uneven, insert insulating washers for leveling.

Connecting the cable (core step)

Connecting the power supply: Locate the motherboard's power connector (usually marked "DC24V," "GND," or "AC110V"; refer to the manual for details). Use a multimeter to confirm that the input voltage meets the motherboard's requirements (mostly DC24V ± 5%). Connect the positive and negative poles correctly (connecting them incorrectly may damage the motherboard's power module). Communication bus connection: Connect the communication lines (such as RS485 or a dedicated bus) between the mainboard and the elevator control panel and hall call panel. Distinguish between "A" and "B" lines or "CAN-H" and "CAN-L" lines, ensure secure connections, and ground the shield at one end to reduce interference.

I/O interface connection: Connect input and output lines for the safety circuit, door lock signal, limit switch, contactor feedback, and other circuits according to the pinout in the manual. Each cable should be crimped to the terminal to prevent short circuits caused by bare wires. After wiring, use cable ties to organize the cables and tie them separately from high-voltage cables (such as motor cables).

Grounding: The mainboard's ground terminal (marked with "PE" or a "ground symbol") should be connected to the control cabinet ground bus with a yellow-green two-color wire. The grounding resistance should be ≤4Ω to prevent damage to the mainboard from static electricity or leakage.