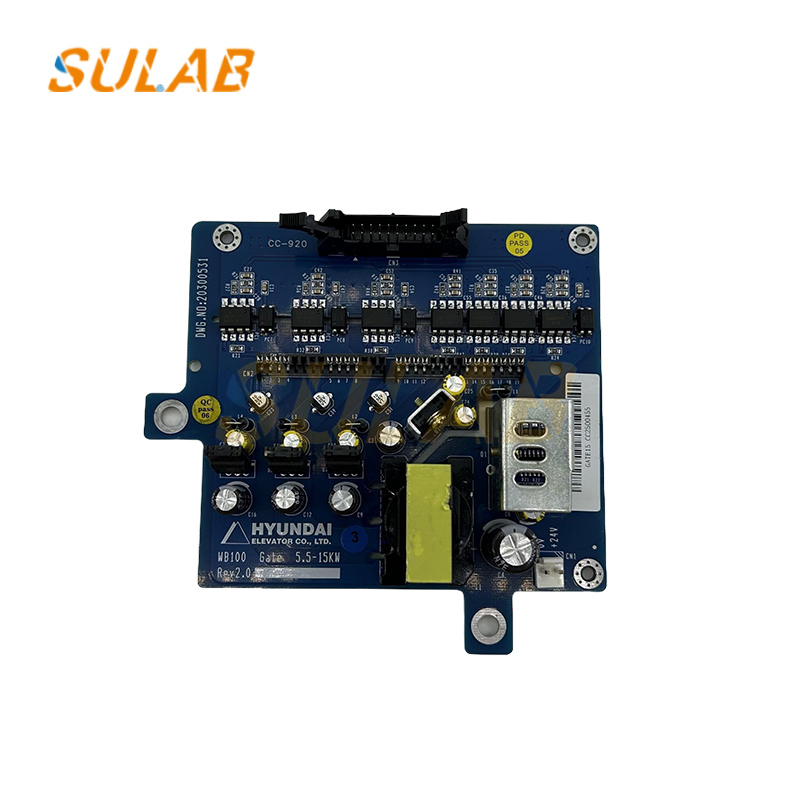

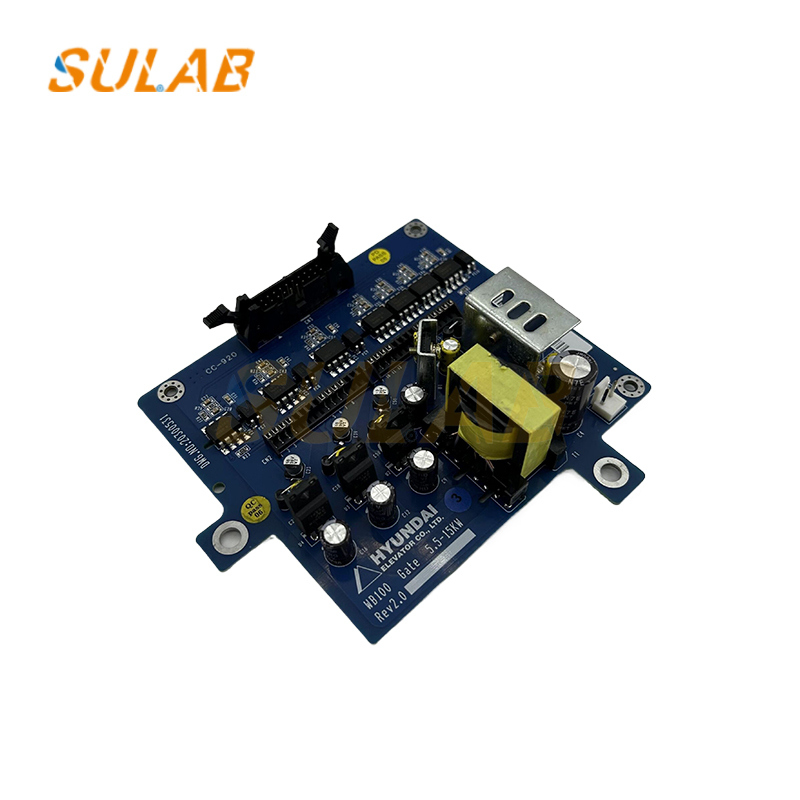

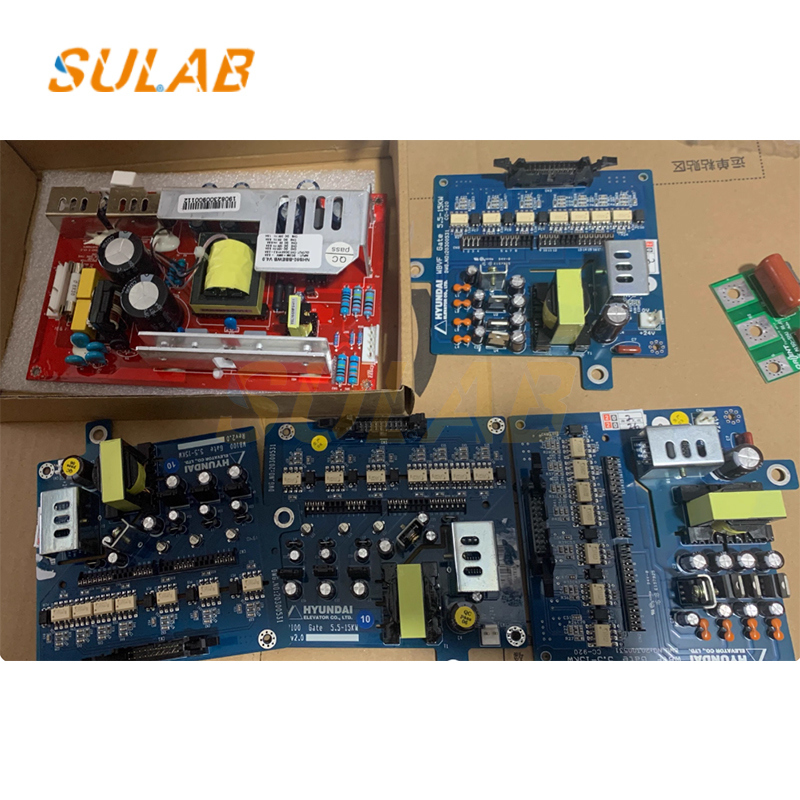

Elevator Drive Board Inverter Board Elevator Drive Board Elevator Accessories PCB Modern Elevator Inverter WB100 Gate CNI 5.5-15KW

-

Highlight

Elevator drive board inverter PCB

,Elevator inverter board with warranty

,Modern elevator drive board 5.5-15KW

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelWB100 Gate CNI 5.5-15KW

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model NumberWB100 Gate CNI 5.5-15KW

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 2-3 working days after payment

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

Elevator Drive Board Inverter Board Elevator Drive Board Elevator Accessories PCB Modern Elevator Inverter WB100 Gate CNI 5.5-15KW

Elevator Drive Board Inverter Board Elevator Drive Board Elevator Accessories PCB Modern Elevator Inverter WB100 Gate CNI 5.5-15KW

The WB100 Gate CNI 5.5-15KW board is a variable frequency control board commonly used in elevator door operator systems. It primarily targets door operator drive scenarios with a power range of 5.5KW to 15KW. Its core functions focus on precise elevator door drive, safety protection, and intelligent control. Details are as follows:

1. Door Operator Drive and Speed Control

As the core control component of the door operator system, it uses variable frequency technology to precisely drive the elevator door motor:

Stepless Speed Control: Automatically adjusts the door operator speed based on elevator operation scenarios (such as the initial opening and closing phase, intermediate phases, and the approaching closing phase), achieving a "quick start - smooth operation - slow stop" process, reducing door impact and noise, and enhancing the passenger experience.

Compatible with Various Motors: Compatible with asynchronous or synchronous motors (depending on the model), it can be configured to match door operator motors of different power (5.5-15KW) through parameter settings, meeting the drive requirements of elevator doors of varying loads and sizes (such as large freight elevator doors and sightseeing elevator glass doors). Precise position control: Combined with the position signal feedback from the door machine encoder, the door opening angle and closing position are precisely controlled to ensure that the door is fully opened or closed, avoiding the risk of people being trapped or the door not closing tightly due to position deviation.

| Brand | SULAB |

| Description | Elevator parts |

| Model | WB100 Gate CNI 5.5-15KW |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

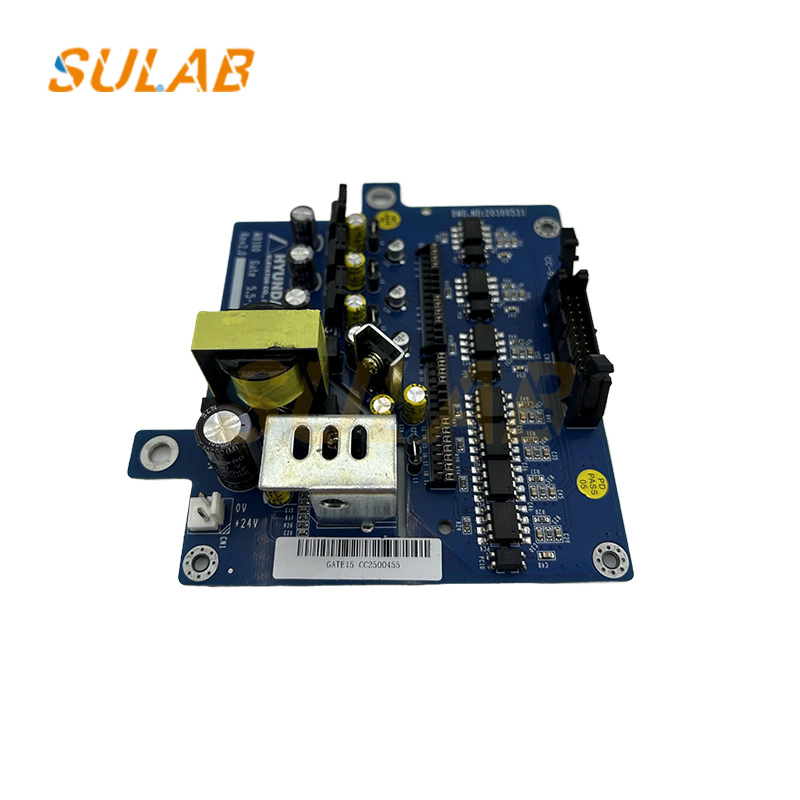

Multiple built-in safety mechanisms ensure reliable door operator system operation:

Overload and overcurrent protection: When the door operator motor is overloaded (e.g., door jamming) or the current exceeds the rated value, the board automatically cuts off output or reduces power to prevent motor burnout or circuit damage.

Overvoltage/undervoltage protection: Monitors the input power voltage and triggers protection when the voltage is too high or too low, preventing power fluctuations from affecting the door operator's operational stability.

Anti-pinch protection: Interoperable with anti-pinch devices such as the elevator door's infrared light curtain and safety touch panel. If an obstruction (such as a passenger's hand or luggage) is detected during the door closing process, the door operator is immediately reversed to open, implementing an anti-pinch function.

Fault diagnosis and feedback: Equipped with self-diagnosis capabilities, when a door operator system fault (such as motor failure, encoder signal loss, or communication interruption) occurs, a fault code is output via indicator lights or the communication interface, allowing maintenance personnel to quickly locate the problem.