Elevator Control Board DPP-200 Model with Variable Frequency Drive and Safety Protection for Smooth Operation

-

Highlight

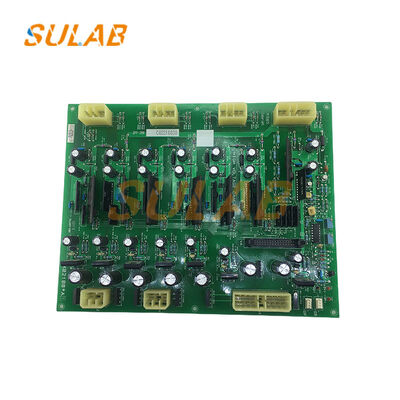

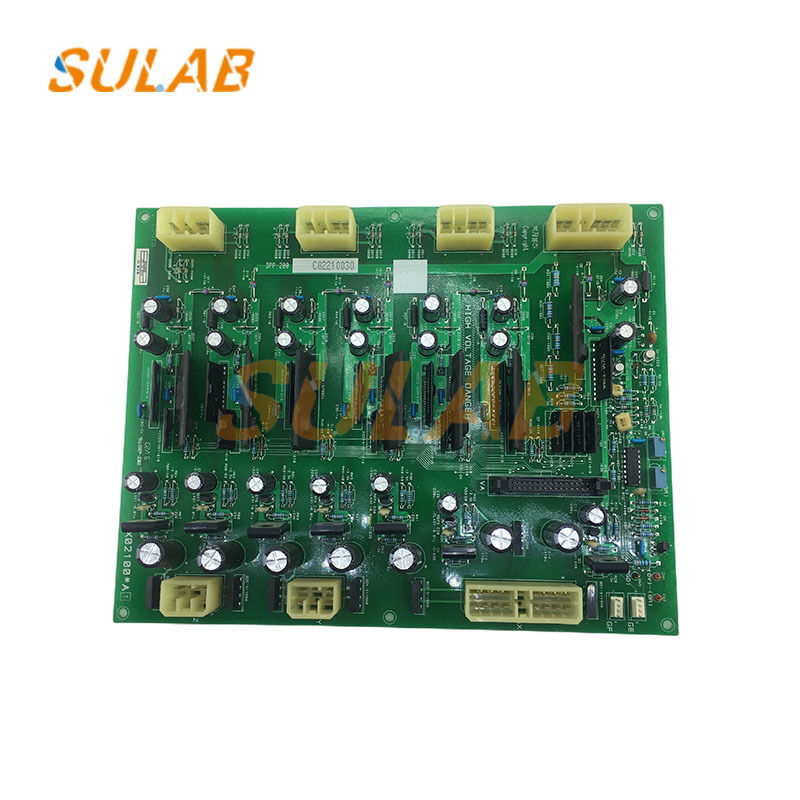

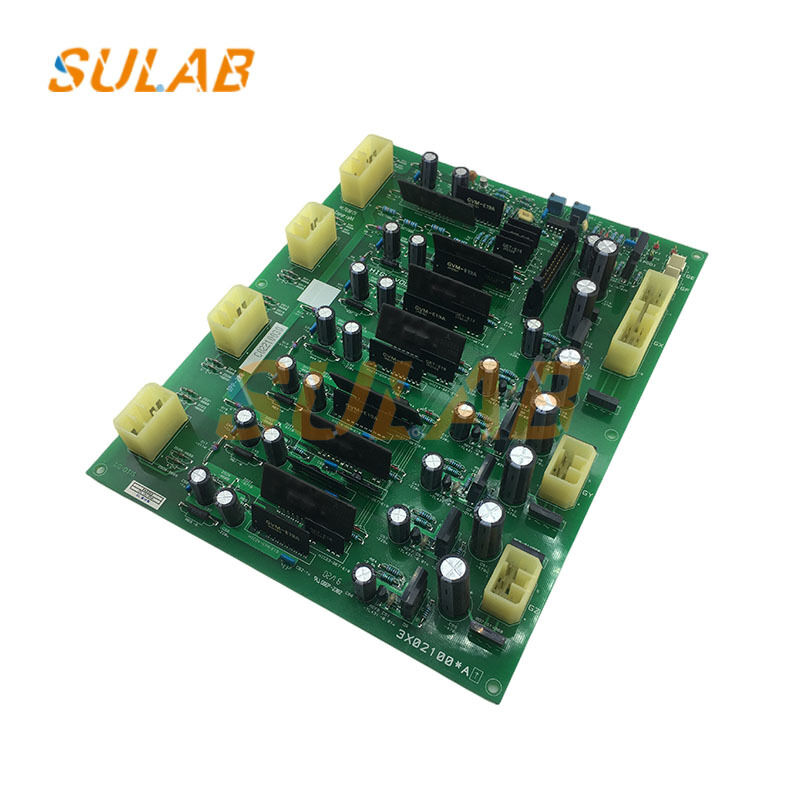

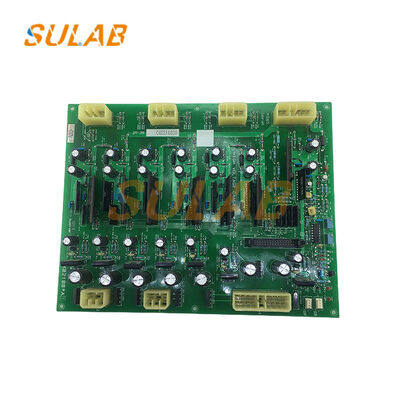

DPP-200 Model Elevator Control Board

,Variable Frequency Drive Elevator PCB Board

,Safety Protection Elevator Drive Board

-

BrandSULAB

-

DescriptionElevator Parts

-

ModelDPP-200

-

MOQ1PC

-

TransportionTNT, UPS, DHL, Fedex, Air, Sea

-

ApplicableElevator

-

PackagesCarton, Wooden Case, Pallet Etc

-

Delivery TimeNormally 2-3 Working Days After Payment

-

WarrantyOne Year

-

Payment MethodCompany Bank, Western Union, Alibaba, Paypal Etc

-

Brand NameSULAB

-

Model NumberDPP-200

-

Minimum Order Quantity1PC

-

Delivery TimeNormally 2-3 working days after payment

-

Payment TermsL/C,D/A,D/P,T/T,Western Union

Elevator Control Board DPP-200 Model with Variable Frequency Drive and Safety Protection for Smooth Operation

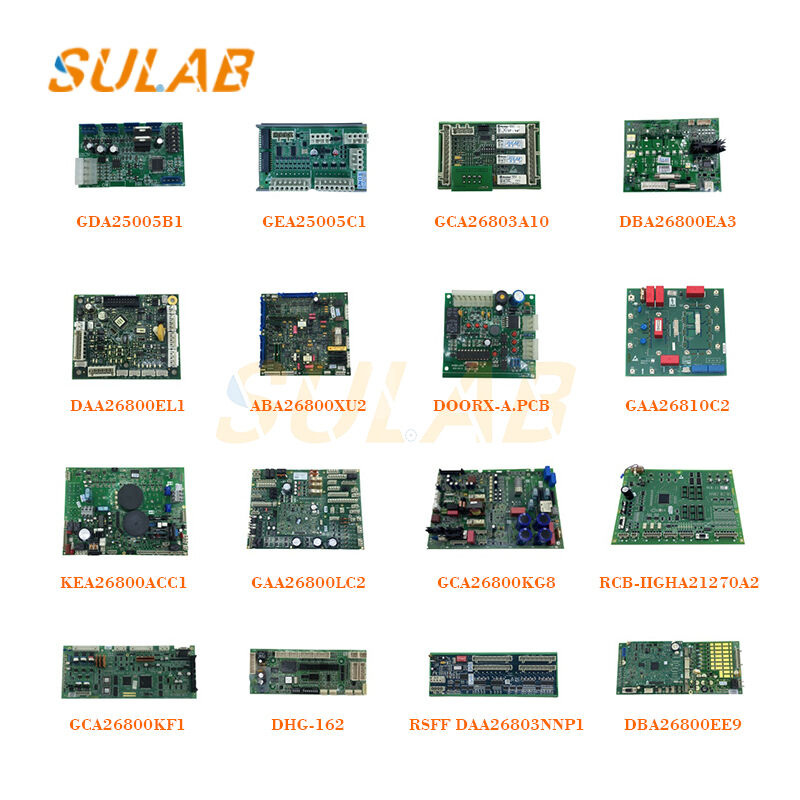

Elevator Control Board PCB Motherboard Elevator Parts PCB LG Elevator Drive Board DPP-200

Core Functions

Traction Machine Variable Frequency Drive: Outputs a three-phase power supply with adjustable frequency and voltage, precisely regulating the traction machine's speed and torque to achieve smooth transitions during elevator start-up, acceleration, constant speed, deceleration, and stopping, adapting to the operational needs of different floors.

Command Reception and Execution: Receives operating commands from the elevator main control system (such as call signals and floor signals), while simultaneously feeding back the operating status of the inverter and motor, ensuring coordinated operation of all elevator components and guaranteeing operational accuracy.

Operation Monitoring and Safety Protection: Monitors parameters such as voltage, current, and temperature in real time, providing overcurrent, overvoltage, overload, overheat, and undervoltage protection functions. Promptly shuts down the elevator in case of abnormalities, ensuring safe operation.

Improved Operating Efficiency and Comfort: Through precise variable frequency control, reduces elevator energy consumption, vibration, and noise, improving passenger comfort.

| Brand | SULAB |

| Description | Elevator parts |

| Model | DPP-200 |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Applicable | Elevator |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

Working Principle

Rectification and Filtering: Converts the input three-phase AC power to DC power. A filter circuit reduces ripple, providing a stable DC power supply for the inverter stage.

Inverter Conversion: Based on the main control commands, power devices such as IGBTs invert the DC power into three-phase AC power with adjustable frequency and voltage, supplying the traction machine motor.

Control Logic Operation: The onboard microprocessor performs control logic operations such as speed and torque based on the elevator's operating status and commands, outputting control signals to adjust the inverter circuit output for precise speed regulation.

Feedback Adjustment: Information such as traction machine speed and position is acquired through encoders and compared with set values. The output is adjusted in real time to ensure the elevator's operating accuracy and stability.